1. The Outline on Characteristic and Application of Stationary Motor Drive Revolve Heavy duty Welding Column and Boom:

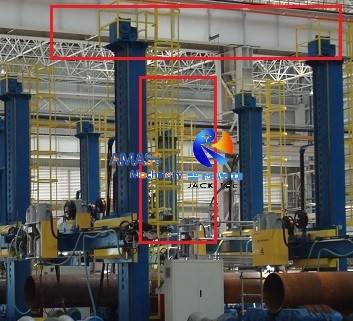

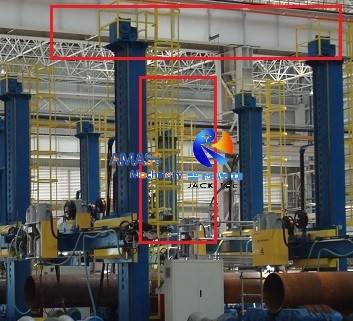

1) The attached master photo was taken on 2 sets of LHZ5050 Fixed Base heavy duty Welding Manipulator. As can be seen from the photo, base bed of these Welding Manipulating Equipment are secured firmly onto workshop floor;

2) For convenience of operating this big size Welding Column Boom, there is walking passage along the whole length of horizonal boom, and climbing ladder along upright column of the Automatic Welding Manipulator;

3) In the previous product section of “Manual Revolve Stationary Heavy duty Welding Manipulator”, we discussed matters concerned with design and production of heavy duty Welding Manipulating Equipment. In this product we will go on to discuss on its operation.

2. Strong Points of User Friendly Operation in Heavy duty Welding Manipulator for Tank Welding:

Same as design, with the increasement of tonnage and dimension of Welding Column and Boom, operation of these big size Tank Welding Machine also poses great challenge on its operation and maintenance, which should be sufficiently safe and convenient. For this reason, we take special care for customers, on easy and convenient operation on these High Efficiency Welding Manipulator:

1) Air Passageway along the Whole Length of Transverse Boom in Heavy duty Welding Column and Boom:

Please check below picture: (Fig.1)

A passage of walking way is installed alongside the horizontal boom. Operators and other working staff can walk on it for doing job on this Precise Welding Column and Boom;

2) Staircase and Overhead Platform in the Welding Manipulating Equipment:

Please check below picture: (Fig.2)

a) An overhead platform is fit at the top of the upright column, for easy maintenance and service on this large size Welding Column and Boom;

b) A staircase for climbing onto the overhead platform is secured alongside the upright column, surrounded with protecting enclosure;

3) Reduce Total Height of the Automatic Welding Manipulator:

a) For Heavy duty Welding Column and Boom, the less total height of the Welding Manipulating Equipment, the more safety and stability of its working process. For this reason, we keep the minimum height of the Welding Manipulator as much as possible. Please check below picture: (Fig.3)

b) Conceivably, for Heavy duty Welding Column and Boom, its total height should be tried to being kept as minimum. For this purpose, we put the column elevating motor inside the bottom fixed base of the Welding Manipulator, instead of installed onto top of the upright column;

c) This also makes maintenance and service job on the Welding Manipulator safe and convenient;

4) Operator Chair in the Heavy duty Welding Column and Boom:

Please check the above picture again:

a) From the perspective of ergonomics and lessening labor intensity, operator can operate this Welding Manipulating Equipment in the position of sitting, instead of standing;

b) When preparing chair for operator, need to fully consider ample allowance for accommodating average height and weight of local people, where the heavy duty Welding Manipulator is put into use;

5)Operation of the Automatic Welding Manipulating Equipment:

a) Considering the large overall dimensions of heavy duty High Efficiency Welding Manipulator, switches/ pushbuttons/knobs should be deployed at both operating panel and remote control pendant of the Welding Manipulating Equipment;

b) Due to series of outsourcing components used in this Tank Welding Machine, including Welding power source/ Seam tracing unit/ Wire feeder/ Flux recovery unit, as well as interlock with other welding equipment, such as Welding Positioner and Welding Roller Bed, integration of these units and equipment into an integral entity Welding Center is of vital importance. It is custom made Precise Welding Column and Boom in each of the application;

c) E-STOP button is deployed close at hand for operators of the Welding Manipulator.

3. Technical Parameters of Stationary Electric Revolve Heavy duty Welding Manipulator:

Standard LHZ Column Electric Revolve Stationary Heavy duty Precise Welding Column and Boom (Welding Manipulating Equipment) |

Model | LHZ 5×5 | LHZ 5×6 | LHZ 6×6 | LHZ 7×7 | LHZ 8×8 |

Max. Boom Vertical Stroke (mm) | 5000 | 5000 | 6000 | 7000 | 8000 |

Max. Boom Horizontal Stroke (mm) | 5000 | 6000 | 6000 | 7000 | 8000 |

Boom Vertical Constant Speed (mm/min) | 1000/ 1500 (For 7×7 and above) |

Boom Horizontal Adjusting Speed (mm/min) | 120 ~ 1200/ 80 ~ 1000 (For 7×7 and above) |

Min. Distance between Boom Bottom and Rail Surface(mm) | 740 ~ 1180/1300 (for 5×6 and above) |

Max. Loading at Front End of Boom (kg) | 200 | 500 | 400 |

Column Revolve Way | Motor drive, 0.17rpm |

Trolley Travel Speed (mm/min.) | N/A |

Internal Span of Trolley Rail (mm) | N/A |