1. Outline on Fixed Base Motor Revolve Medium duty Welding Manipulator:

The three key words describing the Weld Manipulator of this product section are:

1) Medium loading capacity at front end of boom;

2) Fixed base bed of the Automatic Column and Boom;

3) Electric motor drive of column rotation;

In all, this product is a Medium duty Welding Column and Boom with automatic revolving.

2. Application and Applicable Workpieces of Medium duty Welding Column and Boom:

1) With boom moving strokes enlarged from 2000 mm in light duty Welding Manipulator, to 4000 mm strokes in both X axis horizontal direction and Y axis vertical direction, workpieces applicable for this cross slide Weld Manipulator are also turned from small diameter Pipe/ Tube, to larger diameters Tank / Cylinder, and other big scale Vessels;

2) This is the reason why the equipment has the other name of Tank Welding Machine;

3) Under majority conditions, the Medium duty Welding Manipulator work together with Self Adjusting or Bolt Adjusting Welding Rotator, for completing internal and external longitudinal and circumferential welding.

3. Column Revolve in Medium duty Motor Drive Stationary Welding Column and Boom:

1) This is made with motor drive. The motor is of braking type, for conveniently stopping at any angular position reliably during running of the Welding Manipulator;

2) Transmission chain for column revolve is: Braking motor –- Gear –- Slewing support unit – Column, with limit switches for hard security;

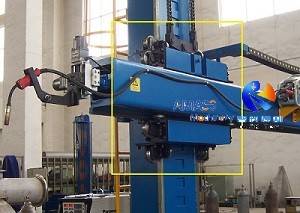

3) Operation is by means of the pushbutton on operating panel of the Welding Manipulator: (Fig.1)

4. Workpiece Loading and Unloading in Welding Column and Boom for Tank Welding:

1) For stationary Welding Manipulator, the max. reach scope of its boom is the full circle surrounding it;

2) So, large diameter and relative heavy weight tanks/ cylinders should be sent to working station beneath horizontal boom of this Tank Welding Machine, utilizing auxiliary unit such as travel crane and sling.

5. Welding Mode in Medium duty Tank Welding Machine:

1) Majority conditions are adopted with large current submerged arc welding, making the equipment a set of Automatic Column and Boom with SAW;

2) When the workpieces are made of materials such as stainless steel and or Al, CO2 GMAW should be selected;

3) Sometimes for welding anti-septic layer or anti-abrasion layer at external surface of workpieces, the Welding Manipulator should be equipped with strip surfacing power supply, making it into a set of Welding Manipulator with Strip Cladding. For detail, please check product section of “LHZ Model Accurate and Fast Welding Manipulator with Strip Cladding”.

6. The Role of Saddle for Boom Traveling in Welding Manipulator:

1) This element has the other name of cross slide. It is the pivot in working of the Welding Column and Boom;

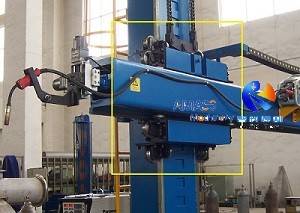

2) The below picture shows how does the saddle looks when fit onto the Medium duty Welding Manipulator: (Fig.2)

3) Horizontal Sliding: As can be seen from the above picture, boom is installed by means of the upper and lower two arrays of eccentric rollers at the front side of the saddle. Or, in other words, top and bottom surfaces of the horizontal boom is snapped between the 4 pieces of eccentric rollers. In this way, during operation of the Welding Column and Boom, horizontal movement of the boom can be guided in smooth, precise, and reliable way;

4) Vertical Sliding: The same is true with elevating movement mechanism of the boom: the external surfaces of vertical column guideway are snapped between the left and right 2 arrays of eccentric rollers at the rear side of the saddle;

5) To have more precise management of boom travel in the period of complicated welding in the Welding Manipulator, these rollers are the kind of eccentric types, which means inching control available for precision manipulation, making the Tank Welding Machine a genuine sense of accurate Welding Column and Boom.

7. Technical Parameters of Fixed Base Motor Revolve Medium duty Welding Manipulator:

Fixed Base Motor Revolve Welding Column and Boom |

Model | LHZ 3×3 | LHZ 3×4 | LHZ 4×4 | LHZ 4×5 |

Boom Vertical Sliding Stroke (mm) | 3000 | 3000 | 4000 | 4000 |

Boom Horizontal Sliding Stroke (mm) | 3000 | 4000 | 4000 | 5000 |

Boom Vertical Sliding Speed (mm/min) | 1000 |

Boom Horizontal Sliding Speed (mm/min) | 120 ~ 1200 |

Min. Distance between Horizontal Boom Bottom Surface and Traveling Rail Top Surface (mm) | 740 ~ 1180 |

Max. Loading at Front End of Boom (kg) | 80 ~ 120 |

Column Revolve Style | Motor Drive, 0.17rpm |

Trolley Travel Speed (mm/min.) | N/A |

Inner Span of Trolley Rail (mm) | N/A |