1. Function of the MP23 Melt Thru Plate Flat Joint Butt Welding Machine:

1) Function: Wuxi JACK MP23 model Plate Butt Welding Joint Machine is used for completing butt joint on any 2 pieces of metal plates, by means of melt thru welding, with the max. welding seam length of 2300mm;

2) Specifications: All the steel plates with width equal to or less than 2300mm, thickness not up to 30mm can be joint with this machine. The length of completed joining plate can be up to 30m;

3) Plate Joint Quality: Strength of joint seam of completed joint plate, delivered from this MP23 model machine is stronger than that of base material, based on the advanced technique of melt thru adopted;

4) The linearity of completed long length joint plate is fully guaranteed, by means of the 5 sets of alignment rollers, installed on input and output conveyors roller table;

5) In a nutshell, both the mechanical property, and physical appearance of completed joint plate, produced from this Melt thru Plate Butt Joining Machine, are superior than that of an integral piece of steel plate from Steel Mill, but with longer length and or wider width.

2. Structure, Working Principle, and Main Function Cells in MP23 Melt thru Plate Butt Joint Welding Machine:

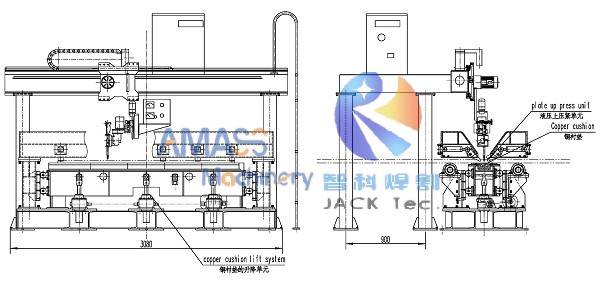

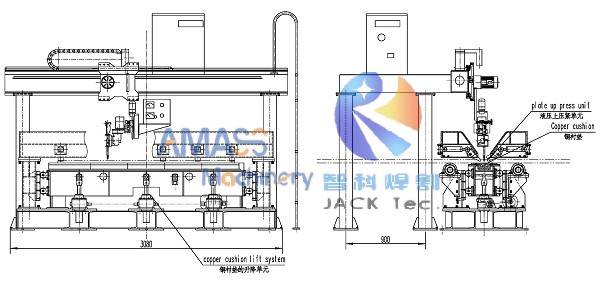

1) Design illustration on main frame of Wuxi JACK MP23 model Plate Butt Joining Machine is as below. Input and output conveyors roller tables not shown here: (Fig.1)

2) Major Units: As can be observed from the above design print, the machine is composed of input and output conveyor, as well as mechanical main frame;

3) 2 Major Function Systems: The triple flame cutting system, and melt thru butt welding system are deployed at inlet and outlet side of the mechanical main frame respectively;

4) In this way, with the moving forward of steel plates going through the Plate Butt Joint Welding Machine, first its edges got beveled by means of triple cutting at its incoming side, then butt welded at its outcoming side, and transported out for offloading.

3. Advanced Technique and Operation of MP23 Melt thru Plate Butt Welding Joint Machine:

1) Wuxi JACK Patent Technique: The critical core technique in this powerful machine is its melt thru welding, which means “One side welding, and welding seam formed on both sides of steel plate”:

Melt thru welding operation in Wuxi JACK MP23 model machine: (Fig.2)

2) Core Working Elements: Shown in the above photo, such leading edge technology is realized with array of copper blocks, which is circulated with cooling water for heat dissipation, during the large current SAW (Submerged arc welding) in the machine;

3) SAW Welding Flux: There are 2 layers of special welding flux, being deposited above and beneath steel plates respectively;

4) Plates for Joint Clamping: Steel plates are pressed firmly on the copper pads, driven under hydraulic system;

5) Operation of this MP23 Flat Butt Welding Machine is by means of user friendly interface of HMI (Human machine interface), shown as below:

Convenient and easy operating interface of Wuxi JACK Plate Butt Joint Welding Machine: (Fig.3)

6) All the process control parameters and specifications for operation can be keyed in by operator through this HMI, directly and conveniently;

7) Effect of welding seam on completed joint plate from this Wuxi JACK MP23 model machine is shown in attached photo, and as below:

Finished butt joint steel plate from Wuxi JACK MP23 Flat Butt Welding Machine: (Fig.4)

4. Mechanical Features of MP23 Melt thru Flat Butt Welding Machine:

1) Input and Output Conveyors Roller Table:

a) Rollers are made from Diameter Φ133mm seamless steel pipes, arranged in interval of 1200mm;

b) Driving section and idler section roller tables are installed in stagger;

c) There are 2 choices of high speed and lower speed available, during feeding in plates into and out of the machine;

2) Alignment Rollers in MP23 Plate Butt Welding Joint Machine:

a) There are 2 units of aligning rollers in input conveyor, and 3 units in output conveyor;

b) Their adjustment is inching mode, realized with manual turning leadscrew;

3) Mechanical Main Body of MP23 Flat Butt Welding Machine:

a) The 2 units of downward acting plate pressing blocks are distributed at outlet of the main body. It is adopted with individual acting style of pressing points, making sure reliable pressing of workpieces of the machine, and little welding deformation;

b) The copper pads block can be lifted up and lowered down integrally, controlled with proximity switch.

5. Main Units of MP23 Melt Thru Plate Butt Joint Welding Machine:

As a turnkey project for butt joining plate from raw material, one set of this MP23 model plate machine has 3 function groups of conveyor/ beveling/ butt welding, which is consisted of:

1) Mechanical main frame: Including box beam with overhead platform, working table, flame triple cutting carriage, and welding carriage;

2) Input and Output Conveyors: 10m length input conveyor, and 35m length output conveyor together with 5 groups of alignment units;

3) Melt Thru Butt Welding System: SAW (Submerged arc welding) power supply, and welding flux system, of the Plate Flat Joint Butt Welding Machine;

4) Flame Triple Cutting System: This is for cutting out beveling on edges of steel plate, which will in turn used as welding groove for the next step of butt welding in the machine.

6. Technical Parameters of MP23 Melt thru Plate Flat Joint Butt Welding Machine:

MP23 Melt thru Plate Butt Joint Welding Machine |

No. | Parameters | Specification | Note |

1 | Applicable Plate Thickness | 8 - 30 mm | Carbon steel, Stainless Steel, or Al Alloy; 6 - 12mm direct joint,16 - 30 with beveling |

2 | Max. Valid Welding Seam Length | 300 - 2300 mm | Or Max. plate width 2.3m |

3 | Max. Length of Joint Plate | 30 m |

|

4 | Melt Thru Welding Speed | 200 - 1200mm/min | Inverter Control |

5 | Plate Moving Idle Speed | 2000 mm/min. |

|

6 | Transverse Transmission | Guided with precision linear guiderail, transmitted with gear and rack couple |

7 | Plate Pressing Form | Hydraulic cylinder |

|

8 | Welding Mode | Melt thru SAW |

|

9 | Flame Triple Cutting | 1 set | For cutting out welding groove |

10 | Conveyor Alignment Unit | 5 sets | 2 sets input,3 sets output |

11 | Alignment Style | Manual CW/ CCW Leadscrew |

|

12 | Input Conveyor | 10 m | 2 segments of roller table, 1 is driving |

13 | Output Conveyor | 35 m | 6 segments of roller table, 3 are driving |

14 | Plate Feeding Speed | 4000 mm/min |

|