A. Welding Manipulator with Specific Welding Modes:

1) From this product section the introduction on special made Welding Column and Boom is from perspective of adopted welding mode. We select the three most often selected welding mode: SAW (Submerged arc welding)/ GMAW/ Strip Cladding, and start from the Welding Manipulator with the widest application: Cross Slide SAW Column and Boom;

2) SAW Welding Manipulator is usually worked in the style of Welding Center, working with Welding Roller Bed and welding system, for completing longitudinal and circumferential welding on external and internal surfaces of tanks/ cylinder/ vessel. Shown as below: (Fig.1)

3) For this reason, SAW Welding Column and Boom can also be named as Tank Welding Machine.

B. Specialties of Automatic Welding Column and Boom with Tank Welding:

1. Applicable Specification Range of Workpieces for Welding Manipulator with Submerged Arc Welding:

Cross Slide SAW Column and Boom is used for high thickness (above 12mm) carbon steel welding, applied as Automatic Welding Manipulator with Tank Welding;

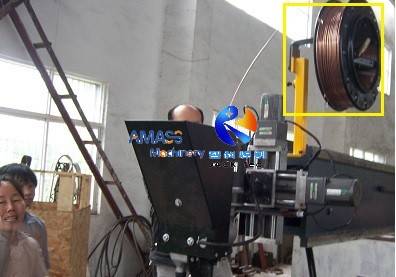

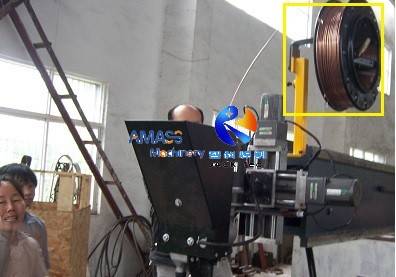

2. Consumables of SAW Welding Manipulator: (Fig.2)

Depending on thickness of tanks/ cylinders/ vessels, large diameter solid wires are consumables of the SAW Welding Manipulator, in the diameters of Φ2.5mm/ Φ3mm/ Φ4mm, etc.;

3. Recommended Configurations of SAW Welding Column and Boom:

In Cross Slide SAW Column and Boom, besides SAW power supply, there should also be SAW wire feeder (usually supplied together with SAW welding power supply as a complete set supplied from supplier):

1) Welding flux recovery unit;

2) Seam tracker is necessary for guaranteeing high quality welding quality in this Tank Welding Machine. For introduction on Seam Tracker, please check the previous product section of “High Precision Welding Manipulator with Seam Tracker”;

3) For attaining satisfactory internal welding quality inside small diameter workpiece, video monitor is a plus to be equipped in this Cross Slide SAW Column and Boom: (Fig.3)

4. Brand of SAW Welding System to be Applied in SAW Welding Manipulator:

Recommended optional choices:

1) Swedish ESAB (LAF1601);

2) U.S.A Lincoln (D.C.1000/ D.C.1500);

3) Chinese HUAYUAN (ZD7-630);

5. Models and Configurations of SAW Welding Column and Boom:

All specifications of the Welding Manipulator are available for submerged arc welding:

1) Motor Drive/ Manual Turning Column Revolving Welding Column and Boom, as well as column non-revolving type;

2) Stationary base, and or Travelling type Welding Manipulator;

3) Light duty / Medium duty / Heavy duty Tank Welding Machine;

6. Arrangement of Welding Function Units in the SAW Welding Manipulator:

Please check below picture, a typical set of Welding Manipulator with Submerged Arc Welding: (Fig.4)

1) “1”— Control console of welding Seam Tracker in the Cross Slide SAW Column and Boom;

2) “2” — Control console of SAW welding power supply, integrating control of wire feeder;

3) “3” — Welding Seam Tracker/ Small cross slide for manipulating torch position/ Flux hopper/ Video Monitor of the SAW Welding Manipulator;

4) “4” — Wire Spool of the Welding Center;

5) “5” — Welding flux recovery unit;

6) “6” — Pipeline for feeding welding flux and recycling flux respectively in the Tank Welding Machine;

7. Application Manner of the SAW Welding Manipulator:

1) The SAW Welding Manipulator can work individually;

2) Besides, for the purpose of fulfilling both internal and external, as well as longitudinal and circumferential welding, this Cross Slide SAW Column and Boom often works together with Welding Rotator and other Welding Equipment. So, there should be interface for communicating with external units in the control system of the Welding Manipulator;

8. Workshop Power Supply for SAW Welding Column and Boom:

SAW welding has large welding power current (1000A/ 1500A). So, at working site where there is Welding Manipulator with Submerged Arc Welding installed, capacity should be at least 100KVA or more, depending on actual practice.

C. Technical Parameters of Welding Manipulator with Submerged Arc Welding:

LHZ SAW Welding Column and Boom |

Model | LHZ 2×3 | LHZ 3×4 | LHZ 4×4 | LHZ 4×5 | LHZ 5×5 | LHZ 5×6 | LHZ 6×6 | LHZ 7×7 | LHZ 8×8 |

Boom Vertical Valid Stroke (mm) | 2000 | 3000 | 4000 | 4000 | 5000 | 5000 | 6000 | 7000 | 8000 |

Boom Horizontal Valid Stroke (mm) | 3000 | 4000 | 4000 | 5000 | 5000 | 6000 | 6000 | 7000 | 8000 |

Boom Vertical Speed (mm/min.) | 1000 | 1500 |

Boom Horizontal Speed (mm/min.) | 120 ~ 1200/ | 80 ~ 1000 |

Max. Loading at Front End of Boom (kg) | 80 | 80~ 120 | 200 | 500 | 400 |

Welding Seam Tracking Range | 100 ~ 200 mm |

Welding Seam Tracking Speed | 200 ~ 250 mm/min. |

Welding Seam Tracking Precision | ± 0.25 mm |

Welding Seam Tracker Applicable Welding Mode | SAW (Submerged Arc Welding) |

Max. SAW Welding Current | 1000A/ 5000A |

SAW Welding Wire | Φ2.5mm/ Φ3mm/ Φ4mm |