1. The Usage of PR40 Model Medium Large duty Pipe Welding Positioner:

1) Model: PR40 is larger size of Pipe Welding Rotator, for welding on cylindrical parts with diameter of 80mm ~1200mm;

2) PR40 Pipe Rotator for welding has the similar structure, degree of freedom, and working principle as PR24;

3) Related Equipment with PR Series Pipe Welding Positioner:

a) Similar to “Circumferential Welding Machine for Pipe” and “Pipe Assembly and Welding Machine”, this PR series pipe welding equipment is also used for circumferential welding on pipe, tube parts. The difference lies in size and specific welding technology of workpiece;

b) The reverse process technology equipment of pipe welding is pipe cutting: “CNC Pipe Cutting Machine”.

2. Technical Specifications of PR40 Model Medium Large duty Pipe Welding Rotator:

In the previous product section of PR24 model, we give specification of PR series pipe welding equipment in terms of workpiece motion. Below are technical parameters of PR series product:

1) Torque of Motions in PR Series Pipe Welding Positioner:

For PR40 Medium Large duty Pipe Rotator,

a) Workpiece revolve torque of Weld Turning Roll is 3750N.m;

b) Workpiece Tilting torque is 7000N.m;

2) Motor Power of Medium Large duty Welding Turning Table:

For PR40 Medium Large duty model,

a) Power of workpiece revolving motor is 750W;

b) Tilting motor power of Welding Turning Table is 400W;

c) And motor power of Weld Turning Roll downward press is 200W;

3) Conductive Device in PR Series Pipe Welding Rotator:

a) For this PR series downward stroke equipment, conductive device is installed on revolving unit of the Pipe Rotator, forming up conductive circuit for welding ground wire;

b) Max. conductive current in the Welding Turning Table can be up to 1000A;

4) Tilting (or Swing) Range of Weld Turning Roll in Pipe Welding Rotator:

One point for emphasis is, for PR40 Medium Large duty model, because of its large diameter of pipe, tube, and elbow, the tilting range of Weld Turning Roll is -35°~+35°, compared with -45°~+45° in PR24 Small Medium duty model.

3. Drive and Transmission in PR Series Pipe Welding Positioner:

On the basis of main units in the PR series automatic equipment, we go on the topic of its drive and transmission for Weld Turning Roll:

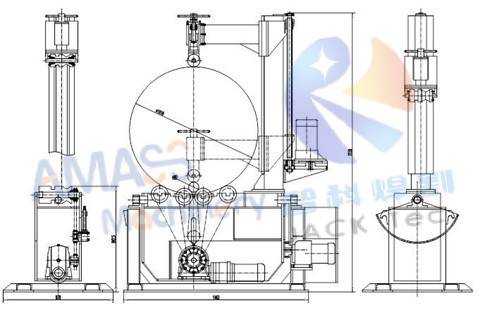

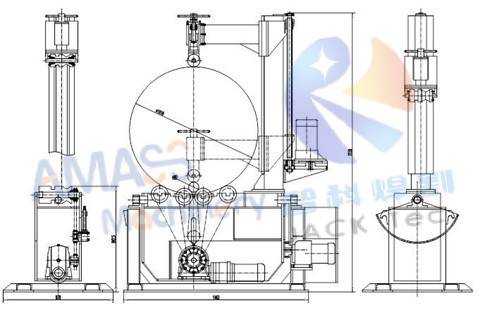

Structure of PR40 model electric Welding Turning Table of Pipe Rotator sees below sketch (PR24 is the same, just in smaller size: (Fig.1)

1) Revolve (or Rotation) of Pipe, Tube, Elbow in Pipe Welding Positioner:

a) Revolving speed of Weld Turning Roll is VFD (Variable frequency drive), and controlled by means of A.C. inverter;

b) Transmission chain in the Welding Turning Table is: Motor→ Worm Gear reducer → Chain and sprocket → The two sets of bottom supporting Weld Turning Roll → Workpiece revolve (or rotation);

2) Tilt (or Swing) of Welding Turning Table in Automatic Pipe Welding Positioner:

a) It is adopted with gear reducer, and has braking function. Which means, Weld Turning Roll and workpiece can be tilted and or to be stopped at any point within its stroke;

b) There are limit switches fit at extreme positions of tilting (or swing);

Swing (Tilt) of workpiece (pipe) in equipment: (Fig.2)

c) Transmission chain is Motor→ Gear reducer→ Pinion → Sector gear→ Workpiece tilt (or swing);

3) Downward Press stroke of Weld Turning Roll in Table Top Pipe Welding Positioner:

a) Downward movement of upper Weld Turning Roll is driven with motor and gear reducer, and transmitted by way of leadscrew and nut;

b) During working period, leadscrew and nut guide sliding shaft moving up and down;

Downward pressing unit: (Fig.3)

c) The downward acting pressing Weld Turning Roll is fit at the front end of the sliding shaft. In this way, the press Weld Turning Roll descends down toward the workpiece, and ascends up to be away from the workpiece;

d) The sliding shaft is encircled in the stationary sliding bush of the Welding Turning Table.

4. Technical Parameters of PR40 Model Medium Large duty Pipe Welding Positioner:

1) With understanding on structure of the PR series universal pipe welding equipment, we will proceed on its operation in the next product section;

2) Below are technical specifications of PR40 Medium Large duty model:

PR40 Medium Large duty Pipe Welding Positioner |

Applicable Workpiece Diameter Range | 80~ 1200mm |

Turning Roller Tilting Range | -35° ~ +35° range, 1.2 rpm angular speed |

Workpiece Motion Torque | Revolving 3750N.m; Tilting 7000N.m |

Workpiece Motion Motor Power | Revolving 750W; Tilting 400W; Elevation 200W |

Revolving Linear Speed of Turning Roller | 0.09 ~ 0.9 rpm |

Workpiece Revolving Range | 0° ~ 360° |

Top Turning Roller Downward | 510mm Stroke, 245 mm/min. speed |

Equipment Overall Dimension | 1.85m Height x 1.27 Length x 0.87m Width |