1. The Outline and Usage on HB series Single Work Table Special Made Welding Positioner:

1) The key word for this Weld Positioning Equipment of Servo Welding Positioner is “Special made”, especially in respect of its mechanical system for the Rotary Welding Table;

2) Customers choosing on this servo drive Special Made Welding Positioner is generally from “Niche and Confidential” application fields, such as Aviation, Military project, Electric Appliance, etc., where high end welding is requisite.

2. This Section of Servo Drive Special Made Weld Positioner can be Generalized as:

1) Same as the previous product of Standard Servo Welding Positioner, the Weld Positioning Equipment hare is also a Single Work Table Welding Positioner with servo drive. In this matter, it is the sibling product of the prior introduced model of Rotary Welding Table;

2) On that basis, this Special Welding Positioner with servo drive has more transformations in its mechanical and transmission system, to meet the demand of pinpoint use from customer;

3) So, this group of Special Made Welding Positioner is “One equipment for one kind of specific workpiece only”, contrary to the first product of “HB series Single Table Top Universal Welding Positioner with chuck”.

3. Technical Summary on the Single Work Table Servo Drive Special Weld Positioner:

1) Control of the Servo Drive Special Made Welding Positioner:

This Rotary Welding Table has the same principle of internal control logic as the prior product of Servo Welding Positioner: Servo motor, encoder detection, negative feedback, electric closed loop control circuit, controller interface connection;

2) Mechanical Structure of the Servo Drive Special Made Welding Positioner:

a) Such Special Welding Positioner has more mutations in external forms including mechanical body and auxiliary units of its Rotary Welding Table;

b) As can be observed from the attached photos, the basic structure of this Weld Positioning Equipment Special Made Weld Positioner with chuck is still with one set of Rotary Welding Table, as compared with the other two groups of important Welding Positioner: The L type Welding Positioner, and Double Table Top Welding Positioner, etc. which will be introduced in subsequent product sections. So, it is a kind of special made Single Work Table Welding Positioner.

4. Examples on Variations of this Servo Drive Special Made Welding Positioner:

1) Splitting type Special Made Welding Positioner: (Fig.1)

In a Welding Positioner made for a military project, a set of split type long length grounding bracket is used, which is installed with sensor and detecting unit, and worked together with the Rotary Welding Table of this Special Made Welding Positioner;

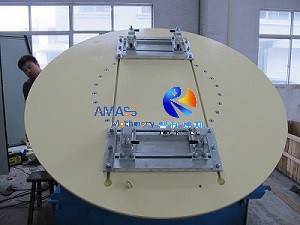

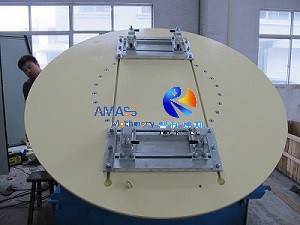

2) Tailor made Fixture in the Special Made Welding Positioner: (Fig.2)

In a set of Single Work Table Special Made Welding Positioner, a pair of dedicated design and produced fixtures are fit on the surface of the Rotary Welding Table, for securing the unique kind of workpiece;

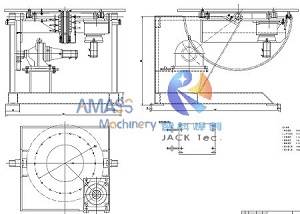

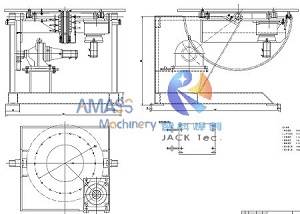

3) Box Structure Special Made Welding Positioner: (Fig.3,4)

a) In a set of Special Made Welding Positioner, the tilting range of its Rotary Welding Table is confined to the range of 0° ~90°, instead of 0° ~120° in conventional Weld Positioning Equipment;

b) And, machine bed of this Special Made Welding Positioner is box type, instead of conventional seat type Weld Positioner, which gives more sturdy body of the Weld Positioning Equipment;

4) Summing up, this Special Made Welding Positioner with chuck can be labelled as combination of “Sophisticated control” and “Flexible Machine Frame” for its Rotary Welding Table.

5. Technical Parameters of the Single Work Table Servo Drive Special Made Welding Positioner:

Below are technical parameters of the HB series Single Table Top Servo Drive Special Made Welding Positioner (Rotary Welding Table):

HB series Single Work Table Servo Special Made Welding Positioner (Weld Positioning Equipment) |

Model | HB1 | HB3 | HB6 | HB12 | HB20 | HB30 |

Loading (kg) | 100 | 300 | 600 | 1200 | 2000 | 3000 |

Revolve speed (rpm) | Depending on servo controller |

Tilt speed (rpm) | 2 | ≈0.9 | ≈0.8 | ≈0.5 | ≈0.4 | ≈0.3 |

Weld Turning Table Dia. (mm) | φ400 | φ600 | φ800 | φ1000 | φ1200 | φ1400 |

Max. Eccentricity (mm) | 100 | 150 | 150 | 200 | 250 | 250 |

Max. Gravity Center Distance (mm) | 150 | 200 | 250 | 250 | 300 | 400 |

Weld Turning Table Tilt Range | 0°~ 120° |

Angular Position Control | ±0.02~ 0.05° |

Revolve Dia. at 900 mm | ≤600 | ≤1000 | ≤1500 | ≤1500 | ≤2000 | ≤2300 |

Weld Turning Table Revolving Speed Adjustment | Revolve and tilt speed is controlled with servo controller |