A. What can SXBJ-15 Long Stroke Sheet Metal Plate Edge Milling Machine do for Customer:

1. Task of Plate Edge Chamfering Machine:

1) XBJ (Single Head) and SXBJ (Double Heads) series Plate End Milling Machine is a kind of general purpose pre-machining equipment, for the task of fulfilling metal plate welding preparation;

2) Here, “General Purpose” not only refers to its wide application of metal plate material, but more importantly, across the industry application of such Plate Edge Beveling Equipment;

2. Why We need Plate Edge Milling Machine?

1) In practical manufacturing industry, for making metal plate fabrication, especially those thickness above 15mm, to get a fully penetration and solid welding seam formed, these metal plates need to be beveled on its edges before welding, and this is what should the Plate End Milling Machine accomplished;

2) The end milled steel plate produced from Wuxi JACK Plate End Milling Machine: (Fig.1)

3) For example, when making plate butt joining to get bigger size of joint plate in MP Series Plate Butt Joint Welding Machine, the 2 pieces of steel plates need to be beveled in Plate Edge Milling Machine, for attaining grooves before butt joint welding;

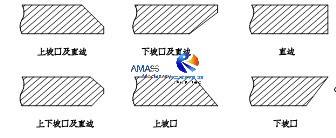

3. Types of Chamfers Available Delivered with the Plate Edge Chamfering Machine:

1) Based on welding technology requirement, there are V/ X/ U types of chamfers which can be machined by means of the Plate Edge Milling Machine, on top / Straight side/ bottom edges of workpiece metal plates;

2) List of Frequently Machined Chamfers made with Plate Edge Milling Machine: (Fig.2)

4. The Recommended Configuration and Workpieces of SXBJ-15 Long Stroke Sheet Metal Plate Edge Chamfering Machine:

1) Application: SXBJ-15 is one of the often selected models Plate Edge Milling Machine by customers in the field of large size workpiece long stroke edge beveling;

2) Workpiece Material: Selecting different materials of facer blade, various materials like carbon steel, alloy steel, stainless steel can be beveled into required chamfer with this Plate Edge Milling Machine;

3) Configuration: For such size of large edge milling stroke, usually the SXBJ-15 Double Heads Long Stroke Plate Edge Milling Machine is equipped with 2 sets of milling head. The single head configuration can not meet the requirement on production efficiency;

4) The max. thickness of workpiece steel plate can be up to 80mm or even 100mm;

5) Thickness of removed layer in one pass of milling head in SXBJ-15 Long Stroke Plate Edge Milling Machine can be up to 5mm;

5. Beveling Angle of SXBJ-15 Long Stroke Sheet Metal Plate Edge Beveling Equipment:

1) Depending on customer requirement, the milling angle of upper edge chamfer in Plate End Milling Machine can be 0~ 45° (Default setting), or 0~ 80° (Tailor made setting);

2) The lower edge beveling in Plate Edge Chamfering Machine has only 1 option: 0~ 45°;

3) The 0~ 45° milling head equipped in SXBJ-15 Long Stroke Sheet Metal Plate Edge Beveling Equipment: (Fig.3)

4) The 0~ 80° milling head equipped in SXBJ-15 Long Stroke Sheet Metal Plate End Milling Machine (Fig.4)

B. Working Features of SXBJ-15 Double Heads Long Stroke Large Sheet Metal Plate Edge Milling Machine:

1. Adjustment of Milling Angle in the SXBJ-15 Plate Edge Chamfering Machine:

1) The default setting in Plate Edge Beveling Equipment is by means of manual turning milling head, together with simultaneously visual inspection according to angle ruler at the lateral side of milling head;

The hardware milling angle ruler along side milling head in Wuxi JACK Plate End Milling Machine: (Fig.5)

2) Sometimes, demanded by customer, Plate Edge Milling Machine milling angle adjustment can also be made with motor drive—a set of 400W motor is equipped for this purpose;

The motor drive milling angle adjustment in Wuxi JACK Plate Edge Milling Machine: (Fig.6)

2. Movement of Milling Heads in the SXBJ-15 Long Stroke Sheet Metal Plate End Milling Machine:

1) Horizontal movement of milling units during working of the SXBJ (Double heads) and XBJ (Solitary head) Plate Edge Milling Machine, which is also edge milling operation in the Plate Edge Chamfering Machine, are driven with motor reducers of 2.2kW, with moving speed controlled with inverter, and adjusted by means of speed knob in the range of 130mm ∼1000 mm/min.;

Make adjustment on edge milling working speed in Long Stroke Plate Edge Milling Machine: (Fig.7)

2) At the completion of current stroke edge milling operation, the idle high speed of its milling carriage moving back to its original point is 4000mm/min,guaranteeing productivity of the Plate Edge Milling Machine;

3. Accurate and Reliable Positioning of Workpiece Steel Plates into the Plate Edge Beveling Equipment:

1) For getting accurate and firm positioning of workpiece, and correspondingly the best quality of sheet metal edge milling, there are fender units installed on working table of the Plate Edge Milling Machine, which are fit at one side of guiderail on the Plate Edge Chamfering Machine mechanical bed;

2) Before loading in steel plate, these fenders can be pulled out by hand and then retreated back into machine bed. Please check picture as below:

3) Fender units for steel plates clamping in the Plate Edge Milling Machine: (Fig.8)

C. Technical Parameters of SXBJ-15 Double Heads Long Stroke Sheet Metal Plate Edge Milling Machine:

Below are technical specifications of the SXBJ-15 Long Stroke Sheet Metal Plate Edge Beveling Equipment:

Model Technical Parameter | SXBJ-15 Double Heads Long Stroke Sheet Metal Plate Edge Chamfering Machine |

Metal Plate Edge Chamfering Length Scope | 500mm ~ 15,000 mm |

Metal Plate Edge Chamfering Width Scope | 200mm ~ 3,000 mm |

Metal Plate Edge Chamfering Thickness Scope | 6mm ∼100 mm |

Milling Angle Range of Straight and Upper Edge Beveling | 0° ~ 45° for standard configuration, And 0° ~ 80° for special configuration |

Milling Angle Range of Bottom Edge Beveling | 0° ~ 45° |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor of Plate End Milling Machine | 5.5 kW |

Milling Head Quantity | 2 sets |

Edge Milling Speed of Plate Edge Milling Machine | 130∼1000 mm/min. (VFD, Inverter Control) |

Idle High Speed of Milling Carriages | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jacks | 25 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |