A. Application of XBJ-4 Single Head High Efficiency Sheet Metal Plate Edge Milling Machine:

1. Position: The XBJ-4 High Efficiency Plate Beveling Machine is one of the common selected models, in product family of XBJ and SXBJ series Sheet Metal Plate End Chamfering Machine;

2. Applied Industry: Due to its compact size of mechanical frame, which is similar to XBJ-3 Single head Sheet Metal Beveling Machine, this XBJ-4 model of Edge Milling Machine can be adapted to various layout of production line in Engineering Machinery facility/ Steel Structure facilities with high flexibility;

3. Applicating Case: For example, XBJ-4 Sheet Metal Plate End Beveling Equipment is usually deployed at beginning working station of T Beam Production Line, or BOX Beam Production Line, etc.;

4. Function of XBJ-4 Single Head Sheet Metal Plate Beveling Machine:

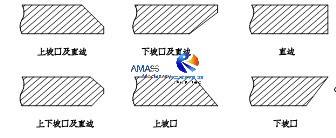

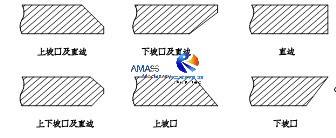

1) Illustration on X / Y/ V beveling completed on edges of sheet metal plate, which can be beveled from Wuxi JACK XBJ-4 Sheet Metal Plate Edge Milling Machine (Fig.1):

2) The finished straight edge beveling produced from Wuxi JACK XBJ model High Efficiency Sheet Metal Plate End Chamfering Machine (Fig.2):

3) The edge grooved metal plates delivered from XBJ and SXBJ series Sheet Metal Beveling Machine can be welded into various forms, with the best strength of welding seam formed. One of the examples is for performing plate butt joining in MP series Plate Butt Joint Welding Machine;

4) The butt jointed steel plate delivered from Wuxi JACK MP20 Plate Butt Joint Welding Machine, the 2 pieces of steel plates should be edge beveled ahead of time in XBJ model Sheet Metal Plate End Beveling Equipment first (Fig.3):

B. Advantages and Uniqueness of Milling Head and its First Time Use in Wuxi JACK XBJ Models Sheet Metal Plate Edge Milling Machine:

1. Like all the other models of XBJ and SXBJ group Sheet Metal Plate End Chamfering Machine, the XBJ-4 single head Sheet Metal Plate Edge Milling Machine is also equipped with 7.5kW milling head, giving it high power for fulfilling high speed and high efficiency chamfering during sheet metal plate end process;

2. The milling head of Wuxi JACK XBJ and SXBJ series Plate Edge Milling Machine has superior advantage not only on the above aspect, but also lies in its structure and performance against that of competitors:

3. Comparison between Wuxi JACK Milling Head in XBJ Series Sheet Metal Plate End Beveling Equipment with Competitors:

1) The milling head of Wuxi JACK Edge Milling Machine is made on the basis of state-of-art technique by first class professional suppliers in the industry, of which its spindle rpm can be adjusted within the range of 6 grades by the operation of turning speed lever:

2) The milling head equipped into Wuxi JACK XBJ models Edge Milling Machine, and its 6 grades revolutionary speed modulation by means of turning speed lever on its top cover: (Fig.4)

3) Comparatively, the form of milling head adopted in Plate Beveling Machine produced by competitors is: There are 2 sets of gear which need to be replaced after uncovering case of the milling head. Such operation on speed change is really time consuming and brings along inferior precision, in view of performance of the XBJ model Sheet Metal Beveling Machine;

4) Below is the illustration on comparison between milling heads between Wuxi JACK and same trade delivered Sheet Metal Plate End Chamfering Machine (Fig.5):

4. First Time Put into Use of the Milling Head in the XBJ Sheet Metal Plate Edge Milling Machine:

After the Plate Edge Milling Machine is delivered to customer site, and before start on the milling head for trial use, be sure to apply 30# mechanical oil of around 12L, to the middle position of oil indicating mark inside the spindle box.

C. Technical Parameters of XBJ-4 Single Head High Efficiency Sheet Metal Plate Edge Milling Machine:

Below are technical specifications of the XBJ-4 Single Head High Efficiency Sheet Metal Plate End Chamfering Machine:

Model Technical parameter | XBJ-4 Single Head Sheet Metal Plate Edge Milling Machine |

Max. Plate End Beveling Length | 4000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Angle Range of Edge Beveling | 0° ~ 60° |

Quantity of Hydraulic Jacks for Pressing Workpieces Sheet Metal Plate | 9 pieces |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 1 set |

Plate thickness for Sheet Metal chamfering | 6∼ 40 mm |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

Idle High Speed of Milling Head Carriage | 4000 mm/min. |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |