1. Outline on Usage of GD20 Rolling Shear Beveling Machine:

1) GD20 Small Plate Edge Milling Machine is the smaller standard model of GD series Hobbing Cutter, for the purpose of small plate beveling before the next step of welding operation;

2) The max. thickness of carbon steel available for being edge milled in GD20 Rolling Shear Beveling Machine is 20mm.

2. Working Process of GD20 Small Plate Chamfering Machine:

1) During small plate edge milling, the hobbing cutter (rolling shearing) of the GD20 Small Plate Beveling Machine revolves under the drive of motor;

2) There is a cavity formed between the top milling cutter, and bottom transmission roller in the mechanical body of the GD20 Hobbing Cutter. During working, the small size plate moves through the cavity, got its edge beveled at the same time;

3) The 2 sets of top position handwheels above the rolling shear is for holding tightly the small plate during work of the GD20 Small Plate Chamfering Machine. Please check below photo: (Fig.1)

4) The one set of bottom handwheel at left hand is for adjusting vertical position of the bottom driving transmission roller, accommodating various thickness of the workpiece in the GD20 Rolling Shear Beveling Machine. Please check below photo: (Fig.2)

3. Strong Points of GD20 Rolling Shear Beveling Machine:

1) The GD20 Rolling Shear Beveling Machine delivers finished product with correct size and clean surface of beveled edge;

2) Compared with other metal plate beveling solutions, such as gas cutting in CG series Triple Flame Cutting Machine, or facer blade in XBJ&SXBJ series Edge Milling Machine, the use of the GD20 Small Plate Chamfering Machine has the advantages of low power consumption, high speed edge milling operation, without the need of follow-up deburring operation;

3) Compared with other Small Plate Beveling Machine, such as Edge Planer and or Gantry Planer, the GD20 Rolling Shear Beveling Machine features in low machine cost and compact size.

4. Convenient and User Friendly Operation of GD20 Small Plate Chamfering Machine:

1) Workpiece fit up step is not necessary in operation of the GD20 Hobbing Cutter;

2) Small plate beveling operation is of high efficiency: 3000 mm/min.;

3) The use of foot pedal switch, together with input and output workpiece rack relieves tedious and cumbersome task of operator of the GD20 Small Plate Edge Milling Machine;

4) No limitation, or request on size of the workpiece, including both its length and width, for being edge milled in the GD20 Hobbing Cutter;

5) On the whole, the efficiency on small plate beveling job in GD20 Small Plate Edge Milling Machine is far better than other way of plate chamfering, including Triple Flame Cutting Machine and XBJ&SXBJ Edge Milling Machine;

6) In all, the GD20 Rolling Shear Beveling Machine is an ideal equipment for small plate welding preparation.

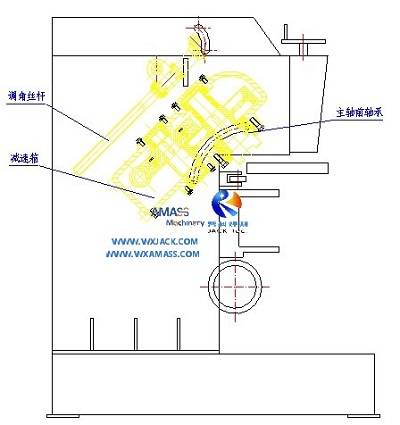

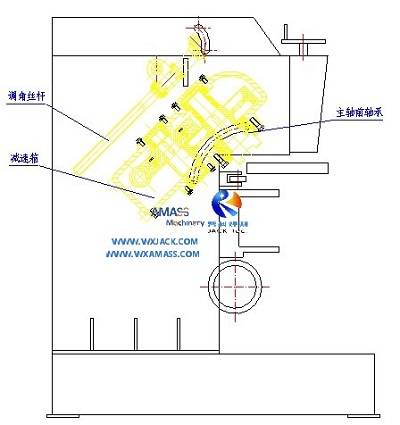

5. Structure of GD20 Small Plate Beveling Machine:

Please check below illustration on the lateral view of the GD20 Rolling Shear Beveling Machine: (Fig.3)

1) The basic unit of GD20 Small Plate Chamfering Machine of Hobbing Cutter is its main body, which is an integral frame of bed and trunk;

2) Working unit and manipulating unit of the GD20 Hobbing Cutter are at the front side of the main body, including rolling shear, angular ruler, four pieces of handwheels for different adjusting task (Plate thickness and others), the big and solid bottom supporting roller;

3) Control elements are integrated into back side of the GD20 Rolling Shear Beveling Machine, making the whole set of Small Plate Edge Milling Machine with compact structure and less bulky size.

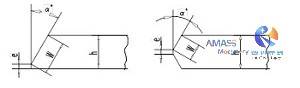

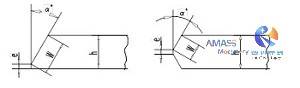

6. Technical Parameters of the GD20 Small Plate Chamfering Machine of Hobbing Cutter: (Fig.4)

GD20 Small Plate Chamfering Machine |

Plate Tension Stress δb (N/mm2) | <400 | >400~500 | >500~600 |

Plate Material | Q235 | Q345 | 1Cr18Ni9TiQ |

Bevel Width W | 20 mm | 16 mm | 12 mm |

Small Plate Chamfering Speed | 2.9 m/min. | 3.1 m/min. | 3.4 m/min. |

Plate Max. thickness h | 40 mm |

Bevel Angle Range α | 25° ~ 55° |

Min. Blunt Size e | 2 mm |

Dimension (L x W x H) | 1240 x 940 x 1500 mm |

Motor model Y112M-4 | 4KW/ 1440 rpm |

Main shaft revolving speed | 7.7 rpm |

Diameter of Milling tool | φ200 mm |