A. Property and Function of SXBJ-16 Large Stroke Double Heads Large Plate Edge Milling Machine:

1. Property: SXBJ-16 is an often selected large model in the product family of XBJ and SXBJ series Edge Milling Machine, second only to SXBJ-18 Plate Beveling Machine;

2. Function of the SXBJ-16 Large Plate Edge Beveling Machine:

1) The SXBJ-16 Large Plate Edge Beveling Machine has max. 16000mm edge milling stroke for making welding grooves;

2) Equipped with 2 sets of milling heads, the welding grooves can be on both top and bottom edges of steel plates, as well as straight edge;

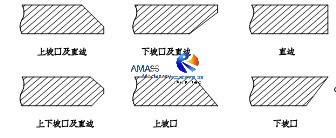

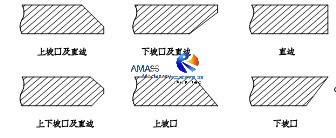

3) The 6 types of classical welding grooves made with SXBJ-16 Large Plate End Chamfering Machine: (Fig.1)

3. The Workpieces of SXBJ-16 Large Plate End Milling Machine:

1) This can be either a single piece of 16000mm or less length steel plate pressed into the Large Plate End Milling Machine, or more than one piece of steel plates pressed together, in the total sum length equals to or less than 16000mm;

2) Pressing a piece of steel plate onto worktable of the SXBJ-16 Large Plate Beveling Machine: (Fig.2)

3) The max. thickness of steel plate to be beveled in this SXBJ-16 Edge Milling Machine is 80mm, width 2500mm;

4) Correspondingly, the max. weight of steel plate to be edge milled in the SXBJ-16 double heads long stroke Edge Milling Machine is 25Ton.

B. Advanced Configuration of SXBJ-16 Large Plate Edge Milling Machine:

SXBJ-16 of this product section is also an advanced configuration Edge Milling Machine. 2 examples are listed as below:

1. Steel Plate Pushing In and Pulling Out System for the Large Plate Edge Beveling Machine:

1) Why You Need this Function Unit: From the previous segment, you know that weight of steel plate for SXBJ-16 Large Plate Beveling Machine is from several tons to 25 ton;

2) Suppose by conventional way of manual job, the pushing into and pulling out the worktable of Large Plate Edge Milling Machine is dangerous for operator, and consumes long time;

3) For this reason, Wuxi JACK develops the solitary owned hydraulic drive automatic steel plate handling system for Edge Milling Machine, which relieves operator of the Large Plate End Chamfering Machine from this dangerous job, and makes the entire material handling operation high efficiency;

4) The hydraulic drive automatic running steel plate loading and unloading system equipped in the SXBJ-16 Large Plate Edge Milling Machine: (Fig.3)

2. Wider Range of Beveling Angle in the SXBJ-16 Large Plate End Milling Machine:

1) Different from the conventional angular scope of 0°~45° adopted in Edge Milling Machine, the 2 sets of milling head equipped in this SXBJ-16 Large Plate Edge Beveling Machine is 0°~80°, which can be found from the attached 6th photo and below;

2) The 0°~80° angle range milling head selected for the SXBJ-16 Large Plate Edge Milling Machine: (Fig.4)

3) Advantage: The 0°~80° angle range milling head is very useful for workpieces steel plate of the Large Plate End Chamfering Machine, which usually have big thickness (80mm), and entails large angle. Please check the attached video on 80° edge milling operation performed in the Edge Milling Machine.

C. Safety Measures Taken in the SXBJ-16 Large Plate Edge Milling Machine:

For this heavy duty Large Plate Edge Beveling Machine, safety is the utmost factor considered during development and daily running of the Edge Milling Machine. Examples of several measures are:

1. Security Fender on Milling Head of the Plate Beveling Machine: (Fig.5)

1) Shown in the above photo, there is security fender installed on the milling head, covering its facer blade into an enclosed area;

2) In this way, hidden risk of operator fingers getting entangled into milling units and hurt with facer blade can be avoided, during work of Edge Milling Machine;

3) Operator Eye Protection: Besides, there will be large volumes of scraps generated when the Plate Edge Milling Machine is in operation. And sometimes operator need to be very close to the milling heads to check the chamfering quality. From this we can see that there exists risk of particles flying out and doing harm to Edge Milling Machine operator eyes. With this security cover, operator eyes can be effectively protected;

2. Emergency Stop Buttons in Edge Milling Machine:

1) For contingency control during working period of Edge Milling Machine, there is Emergency STOP button within easy reach of operator, on the handy operating pendant fit on the milling heads;

2) When emergency happens, this Emergency STOP button can be pressed down the very first time to prevent the problem from expansion to other segment of the Large Plate Edge Beveling Machine.

D. Technical Parameters of SXBJ-16 Double Heads Long Stroke Large Plate Edge Milling Machine:

Below are technical specifications of the SXBJ-16 large stroke Double Heads Large Plate Edge Beveling Machine:

Model Technical Parameter | SXBJ-16 Large Stroke Double Heads Large Plate End Milling Machine |

Max. Plate Edge Milling Length | 16,000 mm |

Max. Width of Steel Plate | 2500 mm |

Plate Thickness for Sheet Metal Chamfering | 6∼80 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Angle Range of Top Milling Unit | 0° to +80° |

Angle Range of Bottom Milling unit | -80° to 0° |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

Idle High Speed of Milling Carriage | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) |

Quantity of Hydraulic Jacks | 27 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |