1. Application Site of HB2000 Heavy duty H Beam Production Line:

1) Business Case: The attached first and second photos are aerial real shot, and design drawing of Wuxi JACK exported to East Europe HB2000 automatic line for welding H Beam production;

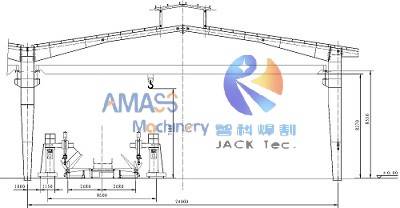

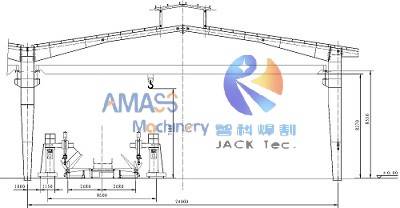

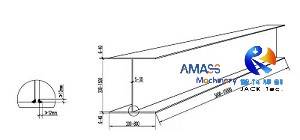

2) Land Occupation: For deployment of all the H Beam Production Machine along this automatic line, it needs around 100m length by 24m width workshop area for installation. The expected height for overhead travelling crane is 8.55m. See below:

Cross view on workshop for deploying fully automatic H Beam Production Line: (Fig.1)

2. Special Point of HB2000 Automatic H Beam Production Line:

1) Characteristics: The HB2000 automatic line is the largest of its kind in terms of both H Beam Production Machine specification, and the corresponding finished welding H Beam;

2) Investment: Conceivably, HB2000 also has the biggest investment. In Steel Structure industry, this line is directly called “Heavy Duty Line”, which is the abbreviation of automatic welding Heavy duty H Beam Production Line;

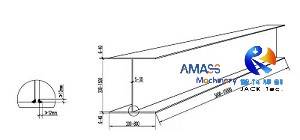

3) Specification: The biggest welded H Beam delivered from this Heavy Duty Line is with H Beam 2000mm web height: (Fig.2)

3. The detailed List on H Beam Production Machine being Applied in HB2000 Automatic Line:

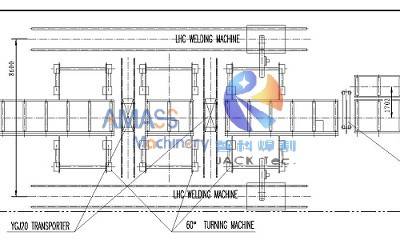

In product section of “HB1500 High Efficiency Automatic Welding H Beam Production Line”, we give the three core H Beam Production Machine adopted in the line. Below is the detailed list on model and quantity of each machinery in a complete set of typical HB2000 fully automatic line:

1) CNC4000 Strip Plate Cutting machine of 4,000mm Span 1 set

2) Z20 H Beam Assembly machine with automatic Spot Welding 1 set

3) Hydraulic drive H Beam 90° Overturning Rack 3 sets / group

4) LHC Column type SAW H Beam Welding Machine 4 sets

5) YGJ15 model motor and hydraulic drive H Beam Travel Cart 4 sets/2 groups

6) Hydraulic drive H Beam 60° Overturning Rack 12 sets/4 groups

7) YF1520 Movable Hydraulic drive H Beam 180° Overturning Rack 4 sets/2 groups

8) HYJ models Motor drive or YTJ model Hydraulic H Beam Straightening Machine 1set

9) Motor drive H Beam Transportation Conveyor 1 set

4. Application Feature of HB Series Automatic Welding H Beam Production Line:

1) Equipment Nature: Of all the above listed equipment, the 1st set of CNC Strip Plate Cutting Machine is a general purpose equipment not limited to being used in H Beam production field. All the remaining products of the 2nd to 9th are all dedicated sole purpose H Beam Production Machine;

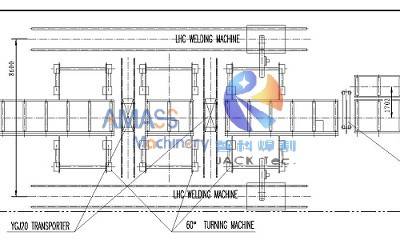

2) Machine Layout: From above can be seen, the arrangement of these machines is in the form of modular type. Customer can determine specific model of each machine for each step based on their H Beam size;

3) For example, the 1st step of H Beam Assembly Machine with tack welding can be Z15/ Z18/Z20, based on size of H Beam web height. This is also true with the 3rd step of H Beam Straightening Machine: Either HYJ40 or HYJ800 model motor drive (for max. 40mm flange thickness) or YTJ series hydraulic drive (For flange thickness up to 40~80mm) can be chosen:

Vertical view on Layout of H Beam Production Line: (Fig.3)

5. Maintenance on Machines in Automatic I Beam Production Line:

1) HB series automatic or semi-automatic line usually takes on heavy workloads (2 shifts working system is not uncommon);

2) For the purpose of guaranteeing on long term stable running of these machine groups, thoughtful daily maintenance plan and strict enforcement is of vital importance for high level running of these H Beam Production Machine;

3) In manual of each set of machine we give suggestion on proper service routine. Customer can draft their TPM (Total preventive maintenance) plan combining practical condition:

Wuxi JACK PHJ15 model 3 in 1 H Beam Welding Machine works at customer workshop: (Fig.4)

4) For example, hydraulic system of H Beam Assembly Machine:

a) Hydraulic oil grade:N32;

b) Observe oil level of oil tank regularly;

c) Please exchange oil regularly. For newly installed H Beam Assembly Machine, after the first use of 6 months, it is necessary to replace new oil; From then on, replace oil every 6 months. Keep hydraulic oil clean. When applying oil, use 120 mesh sieve;

d) When exchange oil, be sure to first empty the oil tank and clean it, then apply new oil.

6. Technical Parameters of HB2000 Automatic H Beam Production Line:

Model | HB2000 Heavy duty H Beam Production Line |

Max. Finished H Beam Web Height | 2000 mm |

Finished H Beam Web Thickness | 6∽32 mm |

Finished H Beam Flange Width Scope | 200∽800 mm |

Finished H Beam Flange Thickness Range | 6∽40 mm (Special thickness of 40~80mm also available with YTJ series hydraulic drive type) |

Finished H Beam Length | 4000 ∽ 12000 mm |

Max. H Beam Weight | 20 Ton. |

H Beam Assembly Machine with Tack Welding | Z20 model |

H Beam Welding Machine | LHC model moving trolley column structure |

H Beam Straightening Machine | HYJ800 model motor drive or YTJ series hydraulic drive |

Transfer of H Beam workpiece among work stations | With Flipping units/ Conveyor/ Travel Cart |