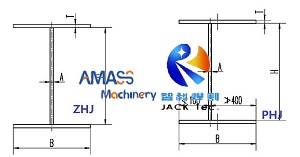

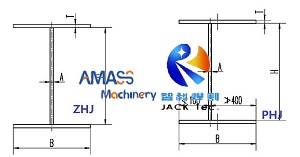

A. The Implication on PHJ and ZHJ Series Vertical Pull Through H Beam Welder and its Working Style:

The phrase “Vertical Pull Through H Beam Welder” gives vivid description on working manner of PHJ and ZHJ models machine:

1. This automatic running multi-functional machine delivers finished welded T Beam/ H Beam with one time passing of workpiece through the entire length of the equipment, from raw materials of long strip boards at input side, to fabricated steel structure working parts at output side of the machine;

1) Input Conveyor of Wuxi JACK PHJ and ZHJ Integral Function H Beam Welding Machine: The loading of the 2nd piece of flange onto fabricated T Beam: (Fig.1)

2) Output Conveyor of Wuxi JACK PHJ18 model 3 in 1 H Beam Fabrication Machine: The completed welded H Beam in vertical orientation: (Fig.2)

2. The above 2 photos explain why we call PHJ and ZHJ series machine as “3 in 1 Vertical Pull Through H Beam Welder machine”: You can get idea on how does it operates in what position of working parts.

B. Process Technology and Facility Condition Updated in PHJ and ZHJ Fit Up Full H Beam Fabrication Machine from H Beam Production Line:

1. Process Route and Required Plant Space for H Beam Production in Conventional Automatic H Beam Production Line:

1) H Beam Production Line produces welded H Beam and T Beam in highly automatic streamline flow way, which presents large volume of finished steel structure members in controllable and expected manner. This is the reason why this automatic machine group get such widespread application for over two decades;

2) Meanwhile, with its divided steps of welding H Beam manufacture in H Beam Production Line:

a) Assembly plus CO2 gas shielded welding --- H Beam Assembly Machine;

b) Submerged arc welding --- SAW H Beam Welding Machine;

c) Flange straightening --- H Beam Straightening Machine;

d) As well as transferring the WIP (Work in process) workpieces among the above 3 stations in the line --- Steel Structure Flipping Equipment;

3) The total throughput time of H Beam production from loading onto line to unloading off line is fairly long;

4) Besides, the installation of automatic H Beam Production Line calls for rather large area of workshop floor, which is from at least 2,400 m2 (100m length by 24m span) to ideal level of 4,800 m2 (200m length by 24m span), this greatly deters many customers from Steel Structure industry who plan to have investment on H Beam Production Line;

5) Wuxi JACK Exported to Russia Heavy duty Automatic H Beam Production Line: (Fig.3)

6) The above analysis gives reason on impetus driving Wuxi JACK developing new product of PHJ& ZHJ series 3 in 1 H Beam Fabrication Machine for customers;

2. Working Principle and Occupied Area of PHJ and ZHJ Pull Through H Beam Welder:

1) The question is, for making welded H Beam, is it possible to integrate the original 3 steps (Assembly and tack welding/ Submerged arc welding/ Straightening) into 1 time operation, and hence eliminate internal material transfer?

2) The answer is YES. And this is the core idea behind development of PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Integral Machine, which plainly indicate its operating theory:

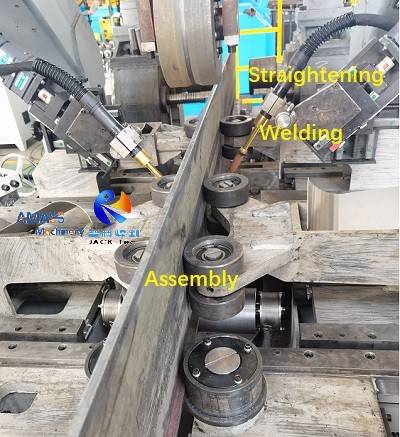

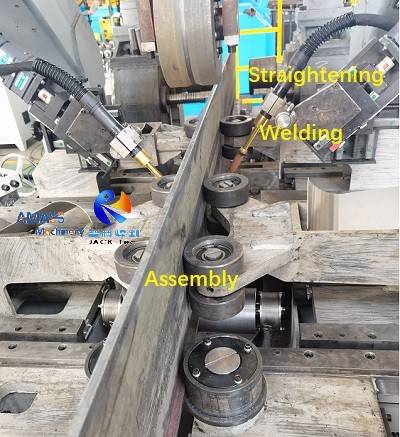

3) Central working area of Wuxi JACK PHJ and ZHJ Integrated Running SAW H Beam Welding Machine, from bottom to top in the photo: Assembly, Welding, Straightening: (Fig.4)

4) So, we can imagine that, in graphical view, the use of PHJ and ZHJ series 3 in 1 machine equals to compressing a line (H Beam Production Line) into a separate point (Vertical Pull Through H Beam Welder);

5) Correspondingly, the necessary land area in facility for installing PHJ and ZHJ models machine is only 100~104 m2 (24m length by 4m width), decreased from the least level of 2,400 m2 for H Beam Production Line we mentioned before, which reduces economical burden of Steel Structure customers in the widest possible manner.

C. Technical Parameters of PHJ and ZHJ 3 in 1 H Beam Fabrication Machine:

Below are technical specifications of PHJ and ZHJ series High Efficiency H Beam Assembly Welding Straightening Integral Machine:

Technical Parameter | PHJ15 | PHJ18 | PHJ20 | ZHJ8015 | ZHJ8018 | ZHJ8020 |

| Integral Function H Beam Welding Machine |

Suitable Web Height | 200∼ 1500 mm | 200∼ 1800 mm | 200∼ 2000 mm | 200∼ 1500 mm | 200∼ 1800 mm | 200∼2000mm |

Suitable Web Thickness | 5∼30 mm | 6∼32 mm |

Suitable Flange Width | 200∼800 mm | 150∼750 mm |

Cross Section Feature | Asymmetric and Symmetric | Symmetric Only |

Assembly Driving Way | Half Automatic: One side oil cylinder, one side leadscrew | Automatic: Both sides oil cylinders |

Suitable Flange thickness | 6 ∼ 40 mm |

Suitable Workpiece length | 3000 ∼ 15000 mm |

Single Pass Welding Seam Height | 8 ~ 12 mm |

Uniform Working Speed (Assembly, Welding Straighten in Phase) | 200∼ 1200 mm/min.(VFD) |

Machine Size(L×W×H) | 28m × 4m × 4.6m | 28m × 4m × 4.9m | 28m × 4m × 5.1m | 28m × 4m × 4.2m | 28m × 4m × 4.5m | 28m × 4m × 4.8m |