A. Special Mechanical Structure of the T Shape Base SXBJ-9 Double Heads Welding Groove Maker Automatic Plate Edge Milling Machine:

1) The working table base of this machine is in the cross section shape of inverted “T”, instead of “L” structure, which is adopted in most majority models of the XBJ and SXBJ series Automatic Plate End Milling Machine. Please check below 2 photos to compare:

2) The flipped “T” structure working table of this special design SXBJ-9 model machine for automatic plate welding groove maker edge milling: (Fig.1)

3) The “L” structure working table of conventional structures: (Fig.2)

B. Design Purpose and Usage of Special Design SXBJ-9 Double Heads Automatic Plate Edge Milling Machine:

1. Why “T” Cross Section Structure of Welding Groove Maker Plate End Beveling Machine?

1) Adopting such special design “T” lateral frame working table in XBJ and SXBJ series machine for automatic plate edge milling, is for the purpose of installing milling head carriages along both sides of machine working table;

2) Because the extended floor adherent bracket in the “T” or “L” cross section structure, is for the purpose of accommodating moving carriage of milling head in Automatic Plate Welding Groove Maker machine, shown in below photo: (Fig.3)

3) In this respect, this special design SXBJ-9 model machine has its both sides of working table assembled with moving milling carriages, shown in below photo: (Fig.4)

2. Usage and Advantages of Special Design SXBJ-9 Welding Groove Maker Automatic Plate End Beveling Machine:

Such special design structure of machine for plate edge milling has 2 main abilities of:

1) Meeting special demand on steel plate edge milling: When both sides of workpiece steel plate should be beveled in the machine, shown in below photo: (Fig.5)

2) Higher Efficiency and Flexibility of Edge Milling Operation: Both sides of the machine worktable can be loaded and performed with edge milling operation this will enhance productivity and more choice on edge milling for customers.

C. Origin and Strong Points of Welding Groove Maker XBJ and SXBJ Automatic Plate Edge Milling Machine:

1. Why it Witness Extensive Application of Automatic Plate End Beveling Machine?

1) Background: XBJ and SXBJ models Automatic Plate Edge Milling Machine is developed out of the requirement and idea of, aiming at replacing Planar Machine, on the aspect of machining welding groove at the edges of workpiece metal plate;

2) Other Name: For this reason, this plate Welding Groove Maker is also named as Automatic Plate End Milling Machine;

3) Advantages: Compared with traditional Planar Machine, the XBJ series machine has the strong points of lower investment, more energy saving, easier maintenance, more convenient operation and finer roughness of finished bevels and chamfers delivered;

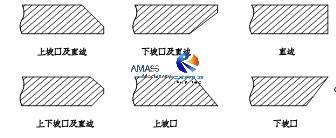

4) The typical often selected types of welding grooves expected from the machine: (Fig.6)

5) The superior quality grooved steel plate produced from Wuxi JACK machine: (Fig.7)

2. Wide Application of Automatic Plate Welding Groove Maker Machine:

1) Ever since its put into market, XBJ and SXBJ models Automatic Plate Edge Milling Machine has gained word of mouth from customers, and sees more and more application across manufacturing industries, and becomes an indispensable 1st operation equipment for making welding grooves;

2) Flexibility of XBJ and SXBJ series Automatic Plate Beveling Machine:

a) Capacity of edge milling welding groove available, angle range from -45° to +90°;

b) Size of workpiece steel plate, from 1,000 mm length up to 18,000mm length, thickness from 6mm to 100mm, thickness up to 3,000 mm;

c) Target Efficiency on producing welding groove in the machine;

3) Variation of Automatic Plate Edge Milling Machine:

a) Overall dimension and model of the machine;

b) Configuration on milling heads and other critical function elements of the automatic machine;

c) Specified Constructure of the machine;

4) All of the above mentioned items can be adaptable to various working site, including indoors workshop and outdoors facility, either as part of a modular cell form Manufacture Line purpose Automatic Plate Edge Milling Machine, or individual running equipment for welding groove maker automatic plate end beveling.

D. Technical Parameters of SXBJ-9 Double Heads T Shape Structure Automatic Plate Edge Milling Machine:

Model Technical Parameter | SXBJ-9 Double Heads Welding Groove Maker Automatic Plate End Milling Machine |

Steel Plate Max. Edge Milling Length | 9,000 mm |

Steel Plate Edge Milling Width Range | 600 ~ 3,000 mm |

Steel Plate Thickness Range for Sheet Metal Welding Groove Maker | 6∼50 mm (Based on customer demand) |

Quantity of Hydraulic Jacks for Pressing Workpiece Steel Plate | 15 Pieces |

Milling Head Quantity | 2 Sets |

Milling Angle Range of Top Milling Unit | 0° to +80° |

Milling Angle Range of Bottom Milling Unit | -45° to 0° |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Feeding Motor | 2.2 kW |

Edge Milling Working Speed | 130∼1000 mm/min. Stepless (VFD, Inverter Control) |

Idle High Speed of Milling Head Unit | 4000 mm/min. Constant |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 mm when make delivery of machine) |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |