A. Output and Working Nature of SXBJ-9 General Use Sheet Metal Plate Edge Milling Machine:

1. Property of XBJ/ SXBJ Models General Use Sheet Metal Plate Edge Chamfering Machine:

1) XBJ and SXBJ series General Use Sheet Metal Plate Beveling Machine belongs to 1st Operation Welding Groove Preparation Equipment, which delivers high quality finished chamfered groove on edges of various kinds of workpieces metal plate:

2) A piece of steel plate has been edge beveled in Wuxi JACK Plate Beveling Machine: (Fig.1)

2. Output of XBJ/ SXBJ Models General Use Sheet Metal Plate Edge Beveling Machine:

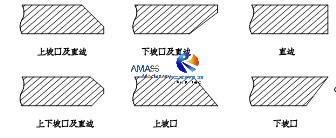

1) By means of adjusting tilting angle of milling heads either upward or downward in the Edge Milling Machine, all the common seen welding grooves can be machined from this Sheet Metal Plate Edge Beveling Machine:

2) The 6 types of X/ V/ K/ Straight edge beveling that can be processed from XBJ and SXBJ models Sheet Metal Plate Welding Groove Preparation Equipment: (Fig.2)

3. Application of XBJ/ SXBJ Models General Use Sheet Metal Plate Edge Chamfering Machine:

1) As a kind of extensively applied Welding Groove Preparation Equipment, the SXBJ-9 Double Heads Steel Plate Edge Milling Machine is one of the mainstream models in practical use;

2) Main advantage of SXBJ-9 Edge Milling Machine lies in its medium size, as well as configuration of two sets of milling heads, which can meet the demand on edge milling majority of workpieces in practical use,;

3) Wuxi JACK SXBJ-9 General Use Sheet Metal Plate Edge Milling Machine is being assembled and validated: (Fig.3)

B. Technical Brief on SXBJ-9 General Use Sheet Metal Plate Edge Chamfering Machine:

1. Installation Orientation of the 2 sets of Milling Heads in SXBJ-9 Double Heads Edge Milling Machine:

1) The attached photos and below pictures denote orientation of the 2 sets of milling heads in SXBJ-9 Sheet Metal Plate Edge Milling Machine, which have different facing directions for performing top edge and bottom edge beveling respectively on steel plate:

2) The assembling orientation of milling head responsible for straight and top edges beveling in Edge Beveling Machine: (Fig.4)

3) The assembling orientation of milling head responsible for bottom edges beveling in Edge Milling Machine: (Fig.5)

2. How does Mechanical Frame of SXBJ-9 Plate Edge Beveling Machine Come into Being:

1) As shown in the attached picture and below picture, mechanical body of the XBJ and SXBJ series Edge Milling Machine is assembled from downward facing pressing beam and horizontal work table;

2) The Sheet Metal Plate Beveling Machine pressing beam and horizontal work table are fit into an integral body by means of two pieces of joining cubic columns at its both ends, and secured with two rows of high strength bolts;

3) The mechanical body of SXBJ-9 Sheet Metal Plate Edge Milling Machine and its assembled indication: (Fig.6)

4) During assembly of Wuxi JACK XBJ and SXBJ series Sheet Metal Plate Edge Milling Machine, there is clear request on this assembling torque; The two cubic columns are strengthened with rounds of up and down stiffeners to make the whole mechanical body of the Sheet Metal Plate Edge Beveling Machine more sturdy and durable;

3. Workmanship of SXBJ-9 Sheet Metal Plate Edge Chamfering Machine:

1) Both of the two sub-assemblies: The pressing beam and work table of the Edge Milling Machine are fabricated from high strength steel plates;

2) The entire structure of the Welding Groove Preparation Equipment has advantages of advanced design, sensible structure and high rigidity;

3) The internal stress of the Sheet Metal Plate Beveling Machine mechanical main frame is relieved through annealing, which guarantees no deformation happening even after long time use of the Sheet Metal Plate Edge Milling Machine;

4. How to Carry Out Groove Making in the SXBJ-9 Sheet Metal Plate Edge Milling Machine:

1) Edge milling process is implemented by means of two sets of milling head, which are installed on its traveling carriages;

2) Movement of the carriages along work table of the Sheet Metal Plate Edge Beveling Machine is guided with up and down two pieces of guide rails in parallelism;

The movement of milling head carriages along mechanical work table of Wuxi JACK Sheet Metal Plate Edge Chamfering Machine: (Fig.7)

3) Of which the top guiderail is precise linear guideway, which is protected with safeguard plates along its whole length, preventing scraps and dusts from falling onto the guiderail and thus affecting precision of the Sheet Metal Plate Edge Beveling Machine;

4) Protection on the bottom guiderail is realized with a two stages scraping unit which is fit on the Edge Milling Machine milling carriage, and clears away foreign particles from the guiderail during edge milling operation, guaranteeing reliable job of this Welding Groove Preparation Equipment.

C. Technical Parameters of SXBJ-9 General Use Sheet Metal Plate Edge Milling Machine:

Below are technical parameters of this SXBJ-9 Sheet Metal Plate Edge Chamfering Machine:

Model Technical Parameter | SXBJ-9 Double Heads General Use Sheet Metal Plate Edge Milling Machine |

Max. Plate Edge Milling Length and Width | 9,000mm Length and 3000mm Width |

Color of Mechanical Frame | Default is JACK Blue; Can be designated |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Taper Hole of Milling Spindle End | ISO 50(7:24) |

Spindle Stroke | 100 mm |

Milling Head Quantity | 2 sets |

Plate thickness for Sheet Metal chamfering | 6∼50 mm (On customer demand) |

Milling Angle of Top Milling unit | 0° to +80° |

Milling Angle of Down Milling unit | -45° to 0° |

Edge Milling Speed | 150∼1000 mm/min. Stepless |

Idle High Speed of Edge Milling Head | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jacks | 15 pieces |

Worktable Width | 500 mm |

Worktable Height | 1050 mm |