CNC-CP series CNC Pipe Cutting Machine is one of the featured and superior products of Wuxi JACK.

A. Usage and Application of Flame Plasma CNC Pipe Cutting Machine:

1. Function of CNC Pipe Intersection Cutting Machine:

CNC-CP series CNC Pipe Cut Machine is for performing pipe cutting and edge beveling:

1) Length Cutting: CNC Pipe Cutting Machine can cut off pipe into segments of required length;

2) Hole Cutting: Round and or elliptic holes of different diameters can be cut in the pipe body, with the effect of straight or oblique beveled rim;

3) Edge Bevel: Rim of pipe can be cut out with required radian and oblique chamfer;

4) Pipe Intersection Joint: The finished work parts delivered from CNC Pipe Cutting Machine can be fabricated into pipe assemblies with cross intersect joint. This is the name “CNC Pipe Intersection Cutting Machine” got from;

2. Operation and Finished Workpieces Cut and Beveled from CNC Pipe Cut Machine:

1) Wuxi JACK exported to America CNC-CP7-3000/12 model 7 Axis CNC Pipe Cutting Machine cut on a piece of Φ2500mm large pipe: (Fig.1)

2) Elliptical beveled hole cut from Wuxi JACK 5 Axis CNC Pipe Flame Plasma Cutting Machine: (Fig.2)

3) Wuxi JACK CNC-CP5-660/12 model 5 Axis CNC Pipe Cutting Machine and its finished cut pipes: (Fig.3)

4) A piece of Φ2000mm large pipe with holes cut from Wuxi JACK CNC-CP7-3000/12 model 7 Axis CNC Pipe Intersection Cutting Machine: (Fig.4)

5) Intersect joint pipe assemblies fabricated from Wuxi JACK CNC Pipe Intersection Cut Machine: (Fig.5)

B. Technical Features of Flame Plasma CNC Pipe Intersection Cutting Machine:

1. Thermal Cutting Technology of CNC Pipe Intersection Cut Machine:

Based on characteristics of pipes, CNC Pipe Cutting Machine utilizes both Oxygen fuel flame and plasma cutting technology:

1) For cutting on big thickness ferrous material: Carbon steel, especially with pipe wall thickness bigger than 50mm, and diameter larger than Φ2000mm. Flame cutting is widely used in corresponding Large Size CNC Pipe Cutting Machine;

2) For cutting on non-ferrous material with smaller thickness: Alloy, Bronze, Stainless steel, especially with thickness less than 30mm. Plasma cutting is adopted in CNC Pipe Cutting Machine;

In this respect, CNC-CP series CNC Pipe Intersection Cutting Machine is also called CNC Pipe Flame Plasma Cutting Machine;

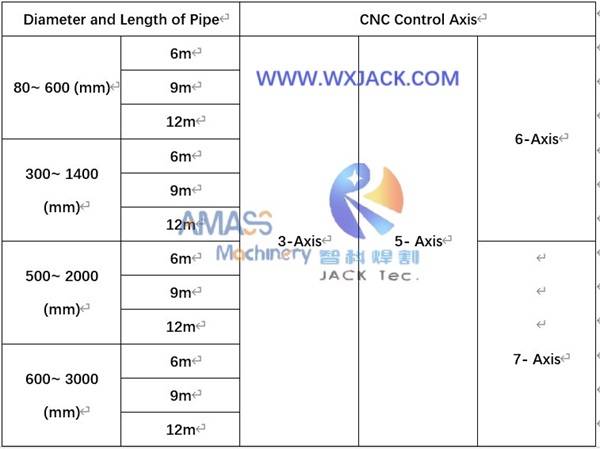

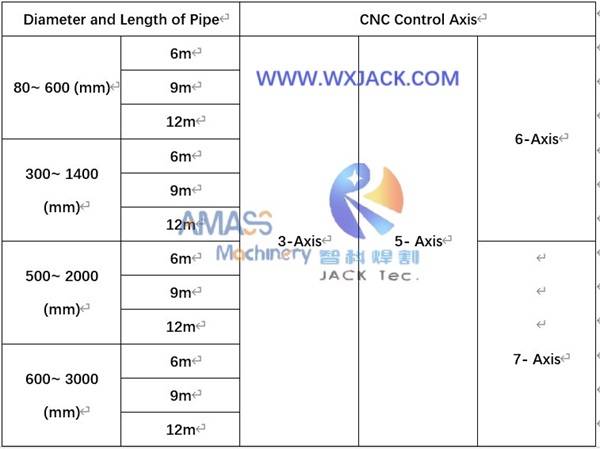

2. CNC Control Axis in Wuxi JACK Flame Plasma CNC Pipe Cutting Machine:

Depending on diameter and thickness of pipe, together with customer demand on cut and beveled form of pipes, there are 4 options of CNC control axis configuration in Wuxi JACK Flame Plasma CNC Pipe Cutting Machine:

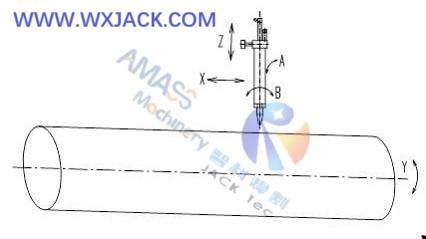

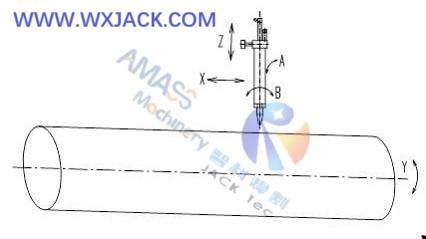

1) 3 Axis CNC Pipe Cutting Machine: Equipped with the three basic control axis of X/ Y/ Z, for managing on cutting torch liner motion in 3 directions;

2) 5 Axis CNC Pipe Intersection Cutting Machine: Added with A axis and B axis, for controlling cutting torch tilting along pipe length and radius direction, so that beveling can be acquired on pipe rims and holes cut:

X/ Y/ Z/ A/ B axis of Wuxi JACK 5 Axis CNC Pipe Cut Machine: (Fig.6)

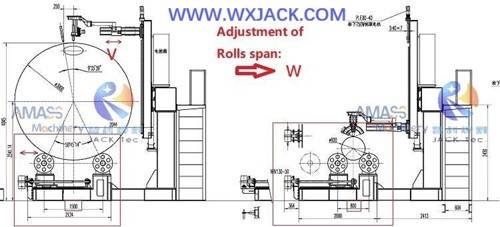

3) 6 Axis CNC Pipe Cutting Machine: Added with V axis for managing on cutting torch linear motion along large pipe radius direction, catering for large diameters pipe;

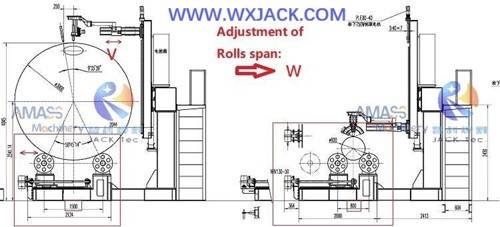

4) 7 Axis CNC Pipe Cutting Machine: Added with W axis for moving workpiece supporting units (Friction roller group) along pipe radius direction, so that large and super large size pipes can be cut reliably:

V/ W axis of Wuxi JACK 7 Axis CNC Pipe Intersection Cutting Machine: (Fig.7)

C. Wuxi JACK Breakthrough on Developing High Quality Mature Product of Flame Plasma Large 7 Axis CNC Pipe Cut Machine:

1. Before the year of 2010, the mature product of CNC Pipe Cutting Machine in the industry and market is for cutting pipe with maximum diameter of Φ1200mm: 3 Axis CNC Pipe Cutting Machine was mainstream product at that time, and 5 Axis CNC Pipe Cutting Machine just saw its inception;

2. From 3/ 5 axis to 7 Axis CNC Pipe Cutting Machine: In the year of 2012, Wuxi JACK took the lead in developing Large Size CNC Pipe Cutting Machine with pipe max. diameter of Φ3000mm, in the form of 7 Axis CNC Pipe Cutting Machine, opening a new era for CP series CNC Pipe Intersection Cutting Machine:

Wuxi JACK CNC-CP7-3000/12 model large 7 Axis CNC Pipe Cutting Machine being installed at customer site: (Fig.8)

3. Application: This kind of advanced technology 6 Axis and 7 Axis Large Size CNC Pipe Cutting Machine are widely used in industries of Oil/ Gas Transportation / Petrochemical/ Pressure Vessel, etc.

4. Wuxi JACK Position: Nowadays, CNC-CP series Flame Plasma CNC Pipe Cutting Machine designed and made by Wuxi JACK are welcomed by customers both in China and Overseas, and gain high recognition from customers.

D. Category of Wuxi JACK Flame Plasma CNC Pipe Intersection Cutting Machine and its Model Selection:

1. Generally speaking, as a Rule of Thumb, below is Guidance on Selecting Proper Models of CNC Pipe Cutting Machine:

1) 3 Axis CNC Pipe Cutting Machine is applied for cutting on small pipes with simple process: Just cut and straight edge bevel, suitable on max. diameter of Φ660mm;

2) 5 Axis CNC Pipe Cutting Machine is applied for cutting on medium to medium large pipes: Length cut and slant bevel, suitable on max. diameter of Φ2,000mm;

3) 6 Axis and 7 Axis CNC Pipe Intersection Cutting Machine are applied for cutting on large size (Diameter and pipe wall thickness) pipes, suitable on max. diameter of Φ3,000mm;

2. Models: Based on diameter of pipes, standard model of the CNC Pipe Cutting Machine falls into 4 ranges, as is indicated in below table;

3. For length of the pipes being cut, standard size is 6m, 9m and 12m. And, we can design and produce non-standard size of the CNC Pipe Cutting Machine based on customer needs.

E. Major Specifications and CNC Control Axis of Wuxi JACK Flame Plasma CNC Pipe Cutting Machine:

For detail introduction, please check each model of product sections in the CNC-CP series CNC Pipe Intersection Cutting Machine: