Background of this Blog on Large Plate Edge Milling Grooving Machine:

1) Business Case: At the beginning of December 2022, Wuxi JACK completed production on 2 sets of Large Plate Edge Beveling Machine, and will make shipment to 2 middle European customers in the same month;

2) This short blog introduces technical specialties of the 2 sets of Sheet Metal Steel Plate Edge Milling Beveling Machine, and its values for customers:

Usage, Value and Technical Specifications of 2 sets of Large Plate Edge Milling Machine;

Technical Specialties of the 2 sets of Large Plate Edge Milling Beveling Machine;

Wuxi JACK Strength on Developing Large Plate Edge Milling Equipment

A. Technical Specifications, Usage and Value of the 2 sets of Large Plate Edge Milling Machine:

The mechanical base bed of SXBJ-6 Large Plate Edge Milling Grooving Machine: (Fig.1)

1) Milling Head: Equipped with two sets of 7.5kW Chinese mainland produced HENGBEI milling head HD750;

2) Max. Effective Working Stroke: In the max. horizontal edge milling stroke of 6000mm;

3) Workpiece Specifications for SXBJ-6 Edge Milling Equipment:

a) Thickness range of steel plates available for being machined in this Edge Milling Grooving Machine is 6~ 50mm;

b) Max. width 2500mm;

c) Correspondingly, max. weight of single piece is 6 Ton;

4) The Milling Angle Range of the 2 Pieces of Milling Heads in SXBJ-6 Sheet Metal Edge Beveling Machine:

a) One piece of milling head has 0° to +85° milling angle scope, for performing upper edge beveling;

b) The other piece of milling head has -45° to +0° milling angle scope, for performing lower edge beveling;

5) Feeding of milling head during running of the Edge Milling Machine is controlled with counter and driven with manual worm reducer;

The mechanical base bed of SXBJ-12 Large Plate Edge Milling Beveling Machine: (Fig.2)

1) Milling Head: Equipped with two sets of 11kW power Chinese TAIWAN produced E-LONG milling head MU-6S;

2) Max. Valid Working Stroke: In the max. horizontal edge milling stroke of 12000mm in this set of large Edge Milling Equipment;

3) Workpiece Specifications for SXBJ-12 Large Plate Edge Milling Equipment:

a) Thickness scope of workpiece steel plates available for being machined in this is 6~ 100mm;

b) Max. width is 2500mm;

c) Accordingly, max. weight of single piece of steel plate is 40 Ton;

4) The Milling Angle Scope of the 2 Milling Heads in SXBJ-12 Large Edge Milling Equipment:

a) One piece of the milling head has machining scope of 0° to +90°, for implementing upper edge beveling;

b) The other piece of the milling head has machining scope of -45° to +45°, for implementing both upper and lower edge beveling in the Edge Beveling Machine;

5) Feeding of milling head during running of the is controlled with counter and driven with manual worm reducer;

6) Pushing in and Pulling out of workpiece Steel Plate: Is made with Wuxi JACK patent and solitary owned hydraulic drive handling system, very applicable for heavy duty Large Plate Edge Milling Machine;

7) Milling Angle Management: The milling angle control precision in these advanced configuration Edge Milling Machine is 0.1°, which is far more precise and accurate than conventional Edge Milling Equipment. We will have a brief introduction on it in the next segment;

3. Usage and Values of the 2 sets of Large Plate Edge Milling Grooving Machine:

As can be seen from the above specifications of the 2 sets of Edge Milling Machine:

1) Medium to large sizes of steel plates can be prepared for welding, by means of edge grooving in these 2 sets of Edge Milling Grooving Machine;

2) Wider range of milling angle in better precision is available for machining completion in the Edge Milling Machine;

3) Heavier cut and more precise intuitive milling are available from each working stroke of cutting, from such heavy duty Large Plate Edge Milling Beveling Machine.

B. Technical Specialties of the 2 sets of Large Plate Edge Milling Beveling Machine:

1. Milling Angle Precision and its Management in the Large Plate Edge Milling Machine:

1) Input of expected milling angle is by means of HMI (Human machine interface) touch screen keying in;

The HMI Touch Screen in SXBJ-12 High Precision Large Plate Edge Milling Machine: (Fig.3)

2) Revolving of milling head is driven with A.C. inverter motor, and protected with proximity switches as well as limit switches;

3) Real time actual angular position of milling head during working of the Edge Milling Grooving Machine is detected with encoder, and displayed in HMI touch screen in digital form, together with indicated on the angle ruler of the milling head;

2. Feeding of Milling Head for Cutting Depth Control in the 2 sets of Large Plate Edge Milling Beveling Machine:

1) In ordinary Edge Milling Machine, this step is made by manually turning hand wheel, and checked with visual inspection by operator of the Edge Milling Equipment;

2) In these 2 sets of High Precision Edge Milling Equipment,

a) The feeding forward of milling head is driven with manual worm reducer;

b) With its displacement controlled and shown with counter;

c) In this way, heavy cutting depth with high precision can be got in such Edge Milling Grooving Machine;

d) Such configuration is featured ability of Wuxi JACK XBJ Series Edge Milling Machine;

e) The worm gear and counter for driving and controlling milling head feeding stroke, in the Large Plate Edge Milling Equipment (Fig.4):

3. Convenient Operation for Fulfilling Powerful Edge Milling Operation in the Wuxi JACK Large Plate Edge Milling Grooving Machine:

1) The Milling Angle Scope in Conventional Sheet Metal Steel Plate Edge Milling Machine:

a) Is 0° to +45° for carrying out straight and upper edge grooving;

b) And -45° to +0° for carrying out bottom edge grooving;

c) Such angle range can only attain conventional milling angle of Edge Milling Grooving Machine;

2) In these 2 sets of Advanced Configuration Edge Milling Machine,

a) Benefitting from the more extensive range of 0° to +90° for carrying out straight and upper edge grooving;

b) And -45° to +45° milling angle for carrying out bottom edge grooving;

c) Any specific beveling angle can be completed in the Edge Milling Machine;

d) Especially 89° to 90° flat surface facing milling: This is very rare angle in operation of Plate Edge Milling Machine. Please check the product linkage in this blog for viewing on its operating video: SXBJ-12 High Precision SXBJ-12 Heavy Duty Plate Edge Milling Machine and photo as below:

e) The 90° flat surface milling and its finished workpiece from SXBJ-6 and SXBJ-12 Large Plate Edge Milling Machine: (Fig.5)

3) Actual milling current in the process of edge milling is displayed in ammeter of the milling head:

The ammeter installed on the E-LONG milling head of the SXBJ-12 Large Plate Edge Milling Beveling Machine: (Fig.6)

4. Precision Process Control Management in SXBJ-6 and SXBJ-12 Large Plate Edge Milling Machine:

1) The counter sensitivity for feeding of milling head is 0.1mm;

2) The adjustment precision of fine tuning handwheel is 0.8mm/ rev.;

3) Slant guiderail is adopted for feeding of milling head platform in this Edge Milling Machine, which has 2 advantages of:

a) Guiderail clearance can be adjusted conveniently, raising edge milling precision;

b) Milling noise during End Milling Machine operation can be damped greatly;

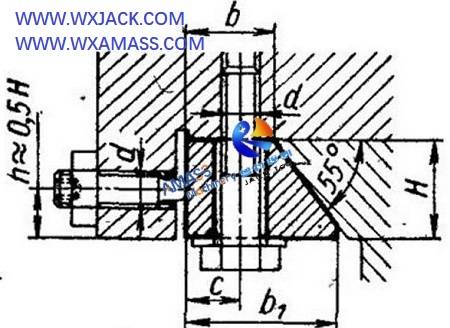

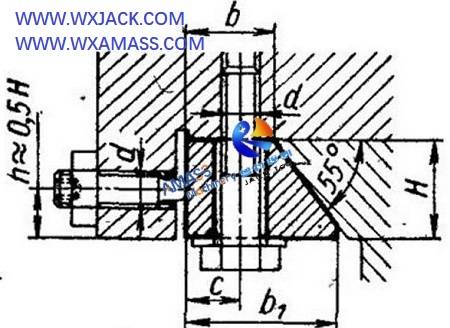

4) The oblique style guiderail in high precision Edge Milling Beveling Machine: (Fig.7)

C. Wuxi JACK Strength on Developing Large Plate Edge Milling Equipment:

1. Importance: XBJ series Edge Milling Machine is superior and advantageous product of Wuxi JACK, and one of primary profit source;

2. Business Achievement: Over the past 2 decades, we have delivered over 800 sets of this range of Edge Milling Machine in various models and configurations for customers in China and worldwide;

3. Leading Edges of Wuxi JACK Plate Edge Milling Equipment:

Compared with sheet metal steel plate Edge Milling Machine from other suppliers in the industry and market:

1) Wider Range of Product for Customer Selection: Not only standard structure and configuration, but also take more exceeding in special design product, just like these 2 sets of SXBJ-6 and SXBJ-12 Edge Milling Grooving Machine we introduced in this blog;

2) Higher precision of milling angle management and cutting depth in the Edge Milling Grooving Machine;

3) User friendly operation, especially on the aspect of heavy and large workpiece handling, with the unique owned hydraulic system of the Edge Milling Machine;

The Wuxi JACK Unique Configuration Hydraulic Drive Workpiece Feeding System for Edge Milling Machine: (Fig.8)

4) Higher power and more Powerful Milling Head adopted in the plate Edge Beveling Machine: 7.5kW to 11kW;

5) Various Cutting Edge Technology adopted in the XBJ series Large Plate Edge Milling Grooving Machine;

For more information, please visit product family of Wuxi JACK Edge Milling Machine.