The Subject of This Blog on Welding Positioner:

1. Security is the foremost issue during development at supplier side, and operation at customer side: It should be paid great attention on by both sides before put into use;

2. In this short blog, we will have a brief discussion on topics involving safety of Welding Positioner:

Importance of Safety Assurance and Related Safety Risk during Operation of Welding Positioner;

Safety Assurance in Wuxi JACK 2 Axis Standard Type Welding Positioner and its Rotary Welding Table;

Safety Assurance in Wuxi JACK 3 Axis L Type Elevating Welding Positioner and its Welding Turning Table;

Safety Assurance in Wuxi JACK 3 ~4 Axis Head and Tail Welding Positioner and its Rotary Welding Table

A. Importance of Safety Assurance and Related Safety Risk during Operation of Welding Positioner:

1. During application of Welding Positioner, especially those with large size and heavy weight Welding Turning Table, for example: L Type Elevating structure models, or Head and Tail double post models, there exist certain degree of safety risk, which should be taken great caution to eliminate ahead of time;

2. Without proper measures, safety risks of Welding Positioner operation will bring along dangers of:

1) Serious working personnel harm;

2) Damage of workpiece and welding equipment, machine tools at running site;

3) Inferior welding quality delivered from Welding Turning Table;

3. The main potential safety risks during running of Welding Positioner can be attributed as:

1) Unreliable sudden unexpected stoppage of Rotary Welding Table in operation period;

2) Sudden falling down of Welding Turning Table and workpiece --- This brings the most serious harm to people and environment;

3) Out of synchronization at both ends of workpiece elevation in Head and Tail Welding Positioner.

B. Safety Assurance in Wuxi JACK 2 Axis Standard Type Welding Positioner and its Rotary Welding Table:

This series products have the biggest using volume in market. Shown as below: (Fig.1)

![Fig1 Welding Positioner 17 Fig1 Welding Positioner 17]()

2. Working Actions of 2 Axis Standard Welding Positioner:

1) 0°~ 360° CW and CCW revolve in adjustable welding speed of Welding Turning Table and workpiece;

2) 0°~ 120° CW and CCW tilt in constant velocity of Welding Turning Table;

3. The Safety Assurance Measures Taken in 2 Axis Standard Welding Positioner:

1) The motors for driving revolve and tilt of Rotary Welding Table and workpieces are all braking type, guaranteeing on its reliable stoppage when necessary;

2) Conductive rod is installed beneath Rotary Welding Table, forming a welding current circuit in the Welding Positioner, and avoiding the issue of electricity leakage: (Fig.2)

![Fig2 Welding Positioner 8 100_9833 Fig2 Welding Positioner 8 100_9833]()

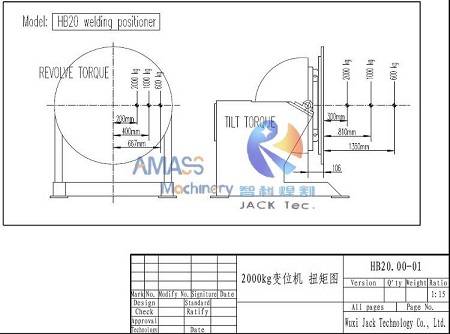

3) Calculate and validate on torque and eccentricity distance sketch of Welding Turning Table, for every model of Welding Positioner: (Fig.3)

![Fig3 Welding Positioner 10- IMG_4906 Fig3 Welding Positioner 10- IMG_4906]()

C. Safety Assurance in Wuxi JACK 3 Axis L Type Elevating Welding Positioner and its Welding Turning Table:

This is a kind of very important welding positioning equipment, with working actions of:

1) Up and down elevating movement of its Rotary Welding Table and workpiece within vertical stroke;

2) 0°~ 360° infinite CW and CCW revolve in adjustable welding speed of Welding Turning Table;

3) 0°~ 360° rotating in fixed speed of Welding Turning Table, shown as below: (Fig.4)

![Fig4 L Type Elevating Welding Positioner 11 P1000211 Fig4 L Type Elevating Welding Positioner 11 P1000211]()

2. The Safety Assurance Measures Taken in Wuxi JACK 3 Axis L Type Elevating Welding Positioner:

1) The motor reducers for driving revolve and rotation of Welding Turning Table and workpiece are all braking type, fully guaranteeing on its reliable stoppage when necessary;

2) The elevation of Rotary Welding Table is driven with hydraulic oil cylinders, and guided with double pieces of precise linear guiderail, shown in below Wuxi JACK 2 Ton L Type Elevating Welding Positioner: (Fig.5)

![Fig5 L Type Elevating Welding Positioner 3 QQ20140819083812 Fig5 L Type Elevating Welding Positioner 3 QQ20140819083812]()

3) Advantages of such design and configuration in L Type Elevating Welding Positioner:

a) Compared with motor drive and leadscrew transmission in L Type models products produced by some other suppliers,

b) Hydraulic oil cylinder drive for Welding Turning Table elevation in Wuxi JACK L Type models products has heavy and strong driving force, as well as reliable working of elevation.

D. Safety Assurance in Wuxi JACK 3 Axis Head and Tail Welding Positioner and its Rotary Welding Table:

1. Head and Tail Welding Positioner is a kind of complicated and large welding equipment, for fabricating on diversified long length and heavy weight structure members;

2. 2 Major Types of Head and Tail Welding Positioner in Application:

1) The 2 sets of upright columns and Rotary Welding Table are connected by means of a horizontal beam: (Fig.6)

![Fig6 Head and Tail Welding Positioner 13 Fig6 Head and Tail Welding Positioner 13]()

2) There is no direct connection between the 2 sets of upright columns (Headstock and tailstock) and Rotary Welding Table in the installed Head and Tail Welding Positioner at customer facility: (Fig.7)

![Fig7 Head and Tail Welding Positioner 4 100_1105 Fig7 Head and Tail Welding Positioner 4 100_1105]()

3. The Main Working Actions of Welding Turning Table in Head and Tail Welding Positioner:

1) Vertical movement of Welding Turning Table and workpiece within its stroke;

2) 0°~ 360° CW and CCW infinite revolve in adjustable welding speed;

3) 0°~ 360° rotating in fixed speed;

4. The Safety Assurance Measures Taken in Wuxi JACK Head and Tail Welding Positioner:

1) Drive System of Rotary Welding Table Elevation and Revolve

a) The motors and reducers for driving Welding Turning Table and workpiece elevation and revolve are all double stage style with self-lock function;

b) The first stage is gear reducer, fully guaranteeing on delivering of heavy torque;

c) The second stage is worm reducer with self-lock function;

d) The elevating servo motors at both sides of Rotary Welding Table and workpiece also have self-lock function;

e) The Rotary Welding Table revolve driving motor is braking type motor;

All of these fully guarantee on reliable braking of both elevation and revolve for Welding Turning Table, in the process of Head and Tail Welding Positioner operation;

2) 1.5~2 Times Safety Margin on Theory Calculation for Model Selection and Mechanical System of Welding Turning Table Elevation and Revolve:

The design and model selection on revolve motor reducer/ mechanical transmission components of Wuxi JACK Head and Tail Welding Positioner all have ample safety margin:

a) Calculation is based on standard of 1.5 times safety margin;

b) The core element (Bearing/ Slewing support) has 2 times safety margin;

3) Transmission of Rotary Welding Table Revolve:

a) The revolve of welding turning table is realized with slewing support in Wuxi JACK Head and Tail Welding Positioner: (Fig.8)

![Fig8 Head and Tail Welding Positioner 1 Fig8 Head and Tail Welding Positioner 1]()

b) Upon its revolve at target angular position, there are 8 pieces of air cylinders around the full circle of slewing support to lock the slewing support firmly;

4) Mechanical Safety Measure for Rotary Welding Table Elevation:

a) Wuxi JACK designs row of safety holes at internal surfaces of the Welding Turning Table;

b) Upon Rotary Welding Table elevated to target level, there are safety pins to have double assurance on completely safety of operation: (Fig.9)

![Fig9 Head and Tail Welding Positioner 2 Fig9 Head and Tail Welding Positioner 2]()

c) These safety pins will be plugged into the safety holes, to avoid the risk of accidental dropping down of Rotary Welding Table and workpiece;

d) The plug-in and pull-out of safety pins is implemented with manual job.

E. Summary on Safety Assurance of Welding Positioner:

1. The safety measures listed in this short blog are just examples for your reference;

2. As a kind of special design Welding Positioner, more safety measures are put into practice in every business case of Wuxi JACK L Type Elevating Welding Positioner, together with Head and Tail Welding Positioner;

3. If you have interest, please visit product family of Wuxi JACK Welding Positioner.