Background of This Blog on H Beam 3 in 1 Production Line:

1. Experience Gained from 3 in 1 H Beam Assembly Welding Straightening Machine Business:

1) Wuxi JACK has successfully made business deal with a South American customer in middle July 2023, on ZHJ-12 model H Beam 3 in 1 Production Line;

2) Although we have accumulated rich experience over the past 15 years during communication with customers worldwide, this South American customer leaves deep impression on us, during technical and commercial discussion on the machine;

3) Because this customer is very careful, which helps us continuously improving on our everyday job;

2. Topics Covered in This Blog on 3 in 1 H Beam Fabrication Machine:

a) Technical Parameters and Supply Range on the ZHJ-12 H Beam 3 in 1 Machine;

b) Business Negotiation on H Beam 3 in 1 Fabrication Machine;

c) Technical Communication on the machine;

d) Summary on Business and Wuxi JACK 3 in 1 H Beam Machine

A. Technical Parameters and Supply Range on ZHJ-12 H Beam 3 in 1 Assembly Welding Straightening Machine:

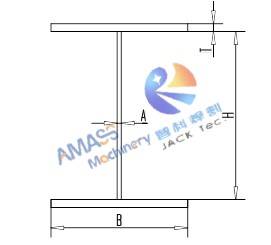

1. Specifications of Welded H Beam by customer: (Fig.1)

![Fig1 Steel Structure H Beam Fabrication Machine 20 Fig1 Steel Structure H Beam Fabrication Machine 20]()

H Beam Specifications | ZHJ-12 |

Flange Thickness T | 6 ~ 40 mm |

Flange Width B | 150 ~ 750 mm |

Web Thickness A | 6 ~ 30 mm |

Web Width H | 200 ~ 1200 mm |

H Beam Length L | 3 000 ~ 12,000 mm |

2. Composition of ZHJ-12 H Beam 3 in 1 Production Line:

1) 1 set of ZHJ-12 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.2)

![Fig2 H Beam 3 in 1 Fabrication Machine 43 Fig2 H Beam 3 in 1 Fabrication Machine 43]()

2) 1 group of hydraulic oil cylinder drive H Beam 90° Overturning Equipment, including 3 pieces of in phase turning racks: (Fig.3)

![Fig3 hydraulic oil cylinder drive H Beam 90° Overturning Equipment 2 4 Fig3 hydraulic oil cylinder drive H Beam 90° Overturning Equipment 2 4]()

3) Spare parts for 1 year use;

4) 1 set of welding flux heating machine;

Expected layout of the H Beam 3 in 1 Production Line at customer workshop: (Fig.4)

![Fig4 H Beam 3 in 1 Production Line 85 Fig4 H Beam 3 in 1 Production Line 85]()

3. Processing Parameters of ZHJ-12 Model H Beam 3 in 1 Assembly Welding Straightening Machine:

Technical Parameters | ZHJ-12 |

Processing Speed (Assembling, Welding, Straightening) | 200 ~ 2000 mm/ min. |

Fast Returning Speed | 2400 mm/ min. |

SAW Welding Position | 50° flat fillet welding |

Welding Wire Size | Φ3.2 ~ 4 mm |

Welding Wire Feeding Speed | 400 ~ 2000 mm/ min. |

Electricity | 3P 440V 60Hz |

B. Business Negotiation on H Beam 3 in 1 Fabrication Machine:

1. Business Start Up on H Beam 3 in 1 Production Line:

1) One day in end of May 2023, the customer first time contacted with us, on workpieces and requirement on the machine and line, for H Beam production;

2) Wuxi JACK engineering team proposed the most fitting proposal and quotation based on customer requirement;

2. Proposal and Quotation Appraisal on H Beam 3 in 1 Assembly Welding Straightening Machine:

1) From end of May to end of June, there is no further response from customer;

2) They were studying on all the proposals and quotations from candidate suppliers;

3. In Depth Technical Communication on H Beam 3 in 1 Production Line:

1) The 2 weeks from end of June to middle July, is the key period on reaching mutual agreement on proposal of the H Beam 3 in 1 Production Line;

2) During this period, customer and Wuxi JACK had detailed communication on technical capability/ performance/ composition/ components brand / spare parts list of the machine and line for H Beam production, which laid solid base on final conclusion.

C. Technical Communication on 3 in 1 H Beam Fabrication Machine:

Customer and Wuxi JACK had extensive discussion on:

1. Straightening Capability of Wuxi JACK H Beam 3 in 1 Fabrication Machine:

1) This is the 1st and critical point distinguishing Wuxi JACK proposed H Beam 3 in 1 Fabrication Machine from other suppliers;

2) Customer demands on max. straightening capacity of 30mm thickness for ASTM A572 Gr.50 Steel, equivalent to Chinese Q345;

3) On this aspect, only Wuxi JACK produced 3 in 1 H Beam machine has such straightening ability;

4) For other candidate suppliers, their counterpart equipment can not attain such heavy straightening capability. So, they can only propose 3 sets of machines to compose H Beam 3 in 1 Production Line (Assembly/ SAW Welding/ Straightening respectively), compared with Wuxi JACK single set of ZHJ-12 model H Beam 3 in 1 machine;

5) Accordingly, customer can save 60% total budget and workshop area, from Wuxi JACK H Beam 3 in 1 Production Line;

2. Technical Superiorities of Wuxi JACK H Beam 3 in 1 Assembly Welding Straightening Machine:

Straightening is not the sole superior unit of Wuxi JACK H Beam 3 in 1 Fabrication Machine. On all the 3 core functions of the machine, we all distinguish ourself from other suppliers:

1) Solid and Precise Assembly in Wuxi JACK 3 in 1 H Beam machine: (Fig.5)

![Fig5 H Beam 3 in 1 Assembly Welding Straightening Machine Fig5 H Beam 3 in 1 Assembly Welding Straightening Machine]()

2) Flexible User Friendly and Accurate Managing on SAW Welding in Wuxi JACK H Beam 3 in 1 Fabrication Machine: (Fig.6)

![Fig6 H Beam 3 in 1 Fabrication Machine Fig6 H Beam 3 in 1 Fabrication Machine]()

3) Unique and Exceeding Structure of Straightening Unit in Wuxi JACK H Beam 3 in 1 machine: (Fig.7)

![Fig7 3 in 1 H Beam Fabrication Machine Fig7 3 in 1 H Beam Fabrication Machine]()

3. SAW Flux Heating Machine Equipped in South American Customer 3 in 1 H Beam Fabrication Machine:

1) The customer city of H Beam 3 in 1 Production Line to be installed has very high humidity: 80% annually average;

2) Correspondingly, SAW flux is very easily to grow wet, which directly affects welding quality of the 3 in 1 machine: Porosity happens very frequently, suppose without any additional measures;

3) For this reason, Wuxi JACK proposed on a set of welding flux heating machine, working as part of the H Beam 3 in 1 machine: (Fig.8)

![Fig8 3 in 1 H Beam Fabrication Machine 21 Fig8 3 in 1 H Beam Fabrication Machine 21]()

4. Electricity of South American Customer Site H Beam 3 in 1 Production Line:

1) Different from Chinese/ Middle and East European countries, in the country of this South American customer, electricity is on the basis of: 440V/ 3Ph/ 60Hz;

2) This is one point sometimes easily to be neglected: Although as supplier, we can quote on the basis of any country and region electricity, we should inform customer from the very beginning that, when it is different from “Conventional” 380V/ 3Ph/ 50Hz, quotation of the entire line will be changed accordingly, because of higher sourcing cost and lead time on main units;

5. Supply Range and Major Part Component Brand of the H Beam 3 in 1 Production Line:

1) On the basis of technical proposal, Wuxi JACK gave customer more detailed list on every unit in the line, and customer checked it one by one;

2) We had some discussions on brand of main units, covering electric A.C. inverter/ Motor reducer/ Hydraulic system;

3) Our goal is, under the precondition of fully guaranteeing performance of the H Beam 3 in 1 Production Line, price of main units should be as reasonable as possible;

4) So, components and main units of the line are sourced from both Chinese and internationally renowned suppliers, agreed by both sides in written form;

6. Spare Parts List on 3 in 1 H Beam Assembly Welding Straightening Machine:

1) Customer is very careful on checking model/ specification/ quantity/ price of any component in the spare list;

2) This is good for avoiding potential disputes in the later stage of order to delivery circle of the 3 in 1 line.

D. Summary on Business and Wuxi JACK 3 in 1 H Beam Assembly Welding Straightening Machine:

1. Over the past decade, Wuxi JACK team is always very pride on our technical strength/ communication skills/ English level/ Feedback rate, during business communication with customers;

2. What We Learned: On the other hand, during this time business negotiation with this South American customer, carefulness and professionalism of the customer not only helps us on delivering consummate H Beam 3 in 1 Production Line, but also helps on improving our internal process.