Background of This Blog on 3 in 1 H Beam Assembly Weld Straighten Integral Machine

1. Recently, during commercial communication on ZHJ15 model 3 in 1 H Beam Fabrication Machine,

An African customer wanted to get answers on below 2 key questions:

1) How much does it cost to produce a piece of H Beam in automatic 3 in 1 H Beam Welding Machine?

2) How long does it take to produce a piece of H Beam in the machine?

The above are the 2 critical points during planning on and introducing any equipment, including the 3 in 1 machine we discussed here;

2. Topics Here on Production Study of 3 in 1 Integral Function H Beam Welding Machine:

In this short blog, we present here the detailed procedure on calculation and analysis for the African customer, focusing on the subject of:

Manufacturing Cost and Cycle Time Calculation on Producing a piece of 12m Length 10mm Thickness H Beam, with Wuxi JACK 3 in 1 H Beam Fabrication Machine;

3. Correspondingly, the train of though to get the conclusion on 3 in 1 H Beam Fabrication Machine,

covers below steps of:

1) Manufacturing Cost Factors on Variable Cost and Cycle Time study;

2) Cost of 3.2mm Diameter Welding Wire;

3) Cost of SJ101 Welding Flux;

4) Cost of Electricity;

5) Total Manufacturing Cost on Manufacturing 1 piece of 12m length and 10mm thickness H Beam in the 3 in 1 H Beam machine;

6) Total Cycle Time on Manufacturing 1 piece of 12m length and 10mm thickness H Beam in the machine;

7) Output of the 3 in 1 Integral Function H Beam Welding Machine per 8 Hours Shift;

8) Note and Summary on Manufacturing Cost and Cycle Time in the 3 in 1 H Beam Assembly Weld Straighten Integral Machine;

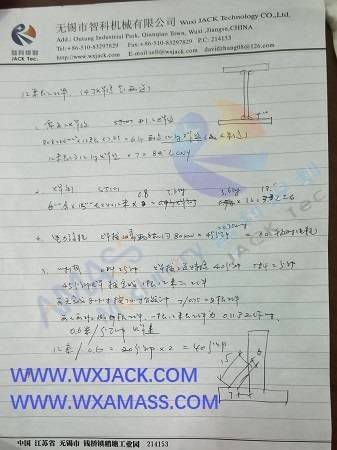

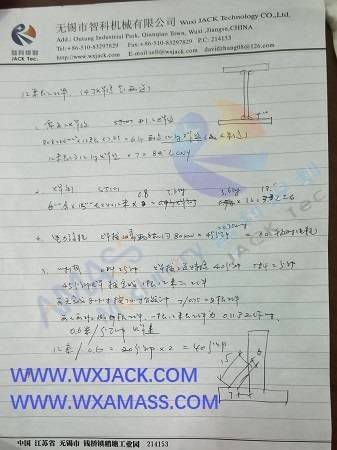

4. Hand Wring Drafts on Calculation and Analysis by Wuxi JACK Engineer on 3 in 1 H Beam Fabrication Machine: (Fig.1)

5. For comprehensive presentation on advantages and cost saving for customers brought along with this 3 in 1 Integral Function H Beam Welding Machine, please check web page “Quick Understanding on Wuxi JACK 3 in 1 H Beam Fabrication Machine”.

A. Manufacturing Cost Factors on Variable Cost and Cycle Time in 3 in 1 H Beam Fabrication Machine:

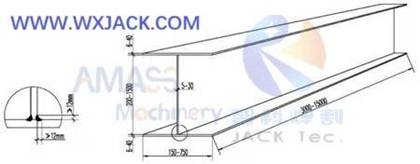

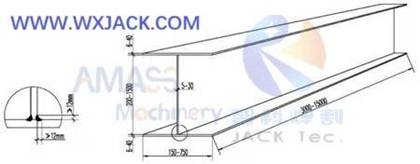

1. Workpiece H Beam Size for calculation and analysis in with the 3 in 1 H Beam machine:

1) 12m total length;

2) Web and flange thickness is 10mm;

3) Design sketch on typical H Beam to be delivered from Wuxi JACK automatic 3 in 1 H Beam Welding Machine: (Fig.2)

2. Variable Manufacturing Cost Factors in 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1) 3.2mm diameter Welding Wire consumed;

2) SJ101 Welding Flux consumed;

3) Electricity consumption in the manufacture of welding H Beam;

4) Manufacturing moment: Laying welding wire and flux in Wuxi JACK Automatic 3 in 1 H Beam Welding Machine: (Fig.3)

B. Cost of 3.2mm Diameter Welding Wire in 3 in 1 Integral Function H Beam Welding Machine:

1. There are 4 pieces of 12m length welding seam on 1 piece of the finished H Beam;

2. Size of Welding Seam Toe on 10mm Thickness H Beam:

8mm height x 8mm width, triangle cross section shape. As shown in hand made sketch;

3. Total welding wire consumed in each pass of welding seam:

(8mm x 8mm) /2 x 12m x 7.85 g/cm3 (Specific gravity of steel) = 3 kg

4. Total welding wire consumed in each piece of H Beam: 3 kg * 4 =12 kg

5. Total cost of 3.2mm diameter welding wire on fabricating 1 piece of H Beam: 7.1 RMB/kg x 12kg= 85.2 RMB

6. Laying 3.2mm diameter welding wire in Wuxi JACK 3 in 1 H Beam Assembly Weld Straighten Integral Machine: (Fig.4)

C. Cost of SJ101 Welding Flux in 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1. Total welding flux consumed on each pass of welding seam with 3 in 1 Integral Function H Beam Welding Machine :

Cross Section (6mm thickness x 15mm width) x 12m x 0.8g/cm3 (Specific gravity of welding flux) = 864 g

2. Total welding flux consumed in producing each piece of H Beam:

864 g x 4 = 3.5 kg

3. Total cost of SJ101 welding flux in producing each piece of H Beam:

3.6 RMB/kg x 3.5 kg= 12.6 RMB

4. Depositing SJ101 welding flux in Wuxi JACK 3 in 1 Integral Function H Beam Welding Machine: (Fig.5)

D. Cost of Electricity in 3 in 1 Vertical H Beam Welder Machine:

1. Welding speed on fabricating 10mm thickness H Beam: 600 mm/ min.

2. Cycle Time on welding Single Pass of Welding Seam: 12m/ (0.6m/min.) = 20 min.

3. Cycle Time on welding one piece of H Beam in the 3 in 1 Integral Function H Beam Welding Machine:

20 min. x 2= 40 min. ≈ 0.67 Hour

(Because 2 passes of welding seams to be fabricated at the same time)

4. Total Power of the 3 in 1 H Beam machine: 80kW

5. Total Electric Power Consumption on producing one piece of H Beam:

80kW x 0.67 Hour= 53.6 KWH

6. Total Electric Power Rate on Producing 1 Piece of H Beam in the 3 in 1 H Beam Fabrication Machine:

6 KWH x 1 RMB/ KWH (Chinese industrial electricity cost) = 53.6 RMB

E. Total Manufacturing Cost on Producing 1 piece of H Beam in 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

Summing up, for producing a piece of 12m length and 10mm thickness welding H Beam in 3 in 1 H Beam Fabrication Machine, the total manufacturing cost equals to:

85.2 RMB for welding wire + 12.6 RMB for welding flux + 53.6 RMB for electricity= 151.4 RMB

F. Total Cycle Time on Manufacturing 1 piece of 12m length and 10mm thickness H Beam in 3 in 1 H Beam Fabrication Machine:

1. One Time Loading workpiece onto the 3 in 1 machine: 1 minute

2. One Time Unloading workpiece from the 3 in 1 machine: 1 minute

3. 1 piece of H Beam production needs 2 times of loading and unloading into and out of the 3 in 1 machine: (1+1) x 2=4 minutes

4. Total Cycle Time on Manufacturing 1 piece of 12m length and 10mm thickness H Beam in 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

40 minutes welding period + (4~5) minutes loading and unloading = 45 minutes = 0.75 Hour

G. Output of the 3 in 1 Integral Function H Beam Welding Machine per 8 Hours Shift:

1. Effective working time within one shift of 8 hours:

7 hours (Suppose 1 hour breaking time per shift)

2. Output of the 3 in 1 machine per 8 Hours Shift:

7 hours/ (0.75 Hour/ Piece) ≈ 9 piece/ Shift

3. Need 1 operator to operate the 3 in 1 H Beam Integral Machine.

Note and Summary on Manufacturing Cost and Cycle Time on 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1. The above calculation and analysis is based on 3 in 1 H Beam Fabrication Machine:

1) Chinese common seen welding technology stipulation on fabricating H Beam, on sizes of welding seam produced. Here, 10mm thickness need 8mm leg size;

2) Quotation on 3.2mm diameter welding wire and SJ101 welding flux to customer;

3) Chinese industrial electricity rate: 1 RMB/ KWH;

2. PHJ and ZHJ series Vertical H Beam Welder are superior, box and advantageous product of Wuxi JACK. For more detail, please visit related product introduction web page.