A. Product Brief on ZHJ8018 Model 3 in 1 H Beam Fabrication Machine:

1. Characteristics and Specification of ZHJ8018 Model 3 in 1 H Beam Fabrication Machine:

1) ZHJ8018 is the medium model of symmetric welding H Beam producing Automatic H Beam Welding Machine (ZHJ series);

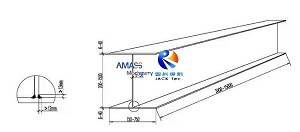

2) The largest height web of welding H Beam made with it is 1800mm. Please check attached picture;

2. Main Units of 3 in 1 H Beam Fabrication Machine:

1) Checking from workpiece incoming side, and in the direction of workpiece going forward, the three main working units in this SAW H Beam Welding Machine is:

a) Assembling unit;

b) SAW/ CO2 Welding unit;

c) Hydraulic Straightening units

Which are installed together into an integral main body without dividing line;

3. Major Process Technology Steps in ZHJ 3 in 1 H Beam Fabrication Machine:

1) The raw materials of one piece of web and two pieces of flanges (Long strip shaped steel plates, cut from CNC Strip Plate Cutting Machine) are sent into ZHJ series H Beam Assembly Weld Straighten Machine by way of its input conveyor 2 rounds;

2) The flanges and web will be got assembled/ welded /straightened within one time pass through:

3) The first round fabricates flange and web into a piece of welding T Beam in cross section of ┷ shape;

4) And the second round fabricates flanges and web into a piece of welding H Beam in cross section of 工 shape, finishing the workpiece into the final product (welding H Beam) of ZHJ series Fit Up Full H Beam Welding Machine.

B. Technical Brief and Compare on PHJ Series versus ZHJ Series 3 in 1 H Beam Fabrication Machine:

1. We introduced Structure/ Main units/ Supporting units/ Welding Mode of PHJ and ZHJ series Automatic Integral H Beam Welding Machine in previous sections of PHJ15 Automatic H Beam Welding Machine, PHJ18 Vertical H Beam Welder, and ZHJ8015 H Beam Welding Machine, please check;

2. PHJ and ZHJ Series Automatic H Beam Welding Machine Comparison:

1) These two sub groups of SAW H Beam Fabrication Equipment (H Beam Assembly Weld Straighten Machine) share the basic same structure and working principle;

2) The Main Difference between ZHJ Series and PHJ Series 3 in 1 H Beam Fabrication Machine:

Lies in assembly unit:

a) PHJ series Vertical H Beam Welder (3 in 1 H Beam Fabrication Machine) has one side of its assembling unit hydraulic drive, and the other side manual handwheel;

b) While ZHJ series Automatic H Beam Welding Machine has its both sides of assembling unit hydraulic driven in phase;

c) This is the reason PHJ series Automatic H Beam Welding Machine can produce both symmetric and asymmetric welding H Beam, while ZHJ series H Beam Welding Machine can only produce symmetric welding H Beam, but in higher assembling efficiency.

C. Quality Control on Wuxi JACK PHJ and ZHJ Series 3 in 1 H Beam Fabrication Machine:

1.Wuxi JACK has comprehensive managing system covering all aspect of quality control (Assembling process, Contamination Control, etc.), and has full time engineer to manage it;

2. We set up series of IPV (Internal Process Validation) for self inspection by operators on their jobs, and QG (Quality Gate) by inspectors, on the critical assembling point of our products, including PHJ and ZHJ series Automatic H Beam Welding Machine;

3. Service Promise on 3 in 1 H Beam Fabrication Machine and Other Products:

1) We have full time customer service quality assurance engineer to deal with all the feedback issues from customers;

2) If ever issues happened with our products, including H Beam Assembly Weld Straighten Machine, we give feedback within 4 hours upon reception of notice from customers;

3) First is ECA (Emergent Corrective Action), then upon investigation, give customer on formal analysis report covering Root Cause Analysis and PCA (Permanent Corrective Action);

4) One of the core legacies of our company is CI (Continuous improvement). With years of experience on PHJ and ZHJ series SAW H Beam Welding Machine, we maintain the always improved status of this Vertical H Beam Welder, making it rendering better service for customers.

Sizes and structure of finished working parts from 3 in 1 H Beam Fabrication Machine: (Fig.1)

D. Technical Parameters of ZHJ8018 Fit Up Full H Beam Welding Machine:

Below are technical specifications of this ZHJ8018 integrated three functions of Automatic H Beam Welding Machine:

Technical Parameter | ZHJ8018 Model 3 in 1 H Beam Fabrication Machine |

Web Height | 200 ∼ 1800 mm |

Web Thickness | 6 ∼ 32 mm |

Flange Width | 150 ∼ 750 mm |

Flange Thickness | 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3000 ∼ 15000mm (At customer demand) |

Working Speed of Assembly/ Welding Straightening | 200∼1200 mm/min.(Stepless, Inverter Control) |

Height of Single Pass Welding Seam | 8~12 mm |

Workpiece (Welding H Beam) Cross Section | Symmetric only |

Overall Dimension(L×W×H)of ZHJ8018 3 in 1 H Beam Fabrication Machine | 28m × 4m × 4.5m |

Driving Mode | Assembly/ Straightening: Hydraulic; Welding: Electric |

Welding Mode | SAW (Submerged Arc Welding)/CO2 MIG/MAG |

Operator | 1 ~ 1.5 (1.5 means a part time support) |