In the 1st photo a set of Wuxi JACK ZHJ8015 model 3 in 1 H Beam Fabrication Machine was being installed in a new workshop.

A. The Purpose of ZHJ8015 Integral Function 3 in 1 H Beam Welding Line and Its Workpiece:

1. H Beam Production Improvement Brought Along with 3 in 1 H Beam Assembly Welding Straightening Machine:

1) Technical Features: ZHJ and PHJ series 3 in 1 H Beam Welding Line is an efficient and powerful equipment applied in Steel Structure industry, integrating the three core steps for making welding H / I / T Beam: Assembly, SAW or GMAW welding, and straightening;

2) In this way, running of Integral Function H Beam Welding Machine can fulfil the benefit of:

a) Raising productivity;

b) Maintaining high standard quality level;

c) Reducing period cost (Workshop land area) and variable cost (Utility cost and manufacturing cost)

For customers;

2. Welding Mode in H Beam Welder 3 in 1 SAW H Beam Welding Machine:

The welding mode in this 3 in 1 H Beam Welding Line is SAW (Submerged arc welding). It has:

1) Large welding current: Working current of 380~ 750A, capacity of up to 1000A;

2) Big welding seam toe size, broad welding cover surface, and high intensity welding seam;

3) Relative high welding speed (100 ~ 1000 mm/min.);

So, ZHJ8015 model 3 in 1 H Beam Fabrication Machine is applicable for producing workpieces in large volume;

3. Output from 3 in 1 H Beam Assembly Welding Straightening Machine:

1) Wide Application: The welding H / I / T Beam manufactured from ZHJ and PHJ series 3 in 1 SAW H Beam Welding Machine is the most universal adopted raw materials in steel structure industry;

2) Specifications of Finished Welding H Beam from 3 in 1 H Beam Fabrication Machine:

Most often have three grades based on H Beam web height size:

a) From the smallest size of 200mm;

b) Up to max. 1500mm/ 1800mm/ 2000mm height;

c) Correspondingly, model of the 3 in 1 SAW H Beam Welding Machine has 3 options of ZHJ/PHJ 8015/ 8010/ 8020 respectively;

4. Related 3 in 1 H Beam Welding Line Based on Workpieces Specifications:

These fabricated welding H Beams can be classified into two broad categories of:

1) Heavy duty Welding H Beam Produced from H Beam Welding Line:

a) H Beam flange thickness higher than 40mm;

b) Single piece weight heavier than 8ton;

2) Light and Medium duty Welding H Beam Fabricated from 3 in 1 H Beam Assembly Welding Straightening Machine:

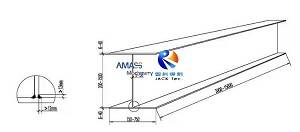

a) Sub- Division: With respect to cross section shape, there are:

Majority of symmetric (Account for over 70%~ 80%);

Minority of asymmetric (Around 20% as the case be);

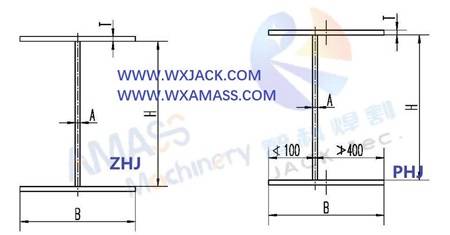

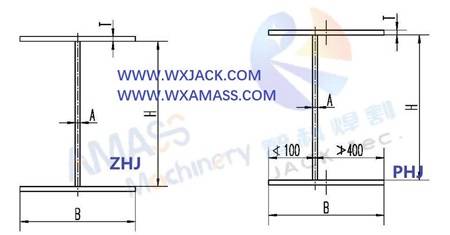

Symmetric and asymmetric cross section H Beam produced from 3 in 1 H Beam Fabrication Machine: (Fig.1)

Here, ZHJ series 3 in 1 H Beam Fabrication Machine (Pull Through H Beam Welder) is dedicated for producing symmetric workpiece;

5. Classification on 3 in 1 H Beam Welding Line for Producing Welding H Beam:

1) For manufacturing heavy duty H / I / T Beams, the traditional automatic and semi-automatic 3 in 1 H Beam Welding Line:

It is composed of three basic machines for fulfilling perations of:

a) H Beam Assembling and CO2 tack welding;

b) SAW (Submerged arc welding);

c) H Beam Flange Straightening;

Together with Transferring Carts and Overturning Racks;

2) For producing light and medium duty workpieces, the ZHJ series Integral Function H Beam Welding Machine (3 in 1 H Beam Assembly Welding Straightening Machine) is perfect solution.

B. Constructure of ZHJ Series 3 in 1 SAW H Beam Welding Machine:

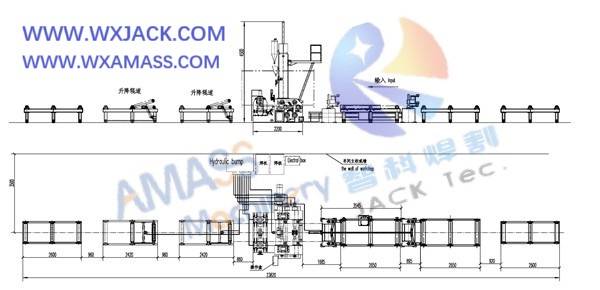

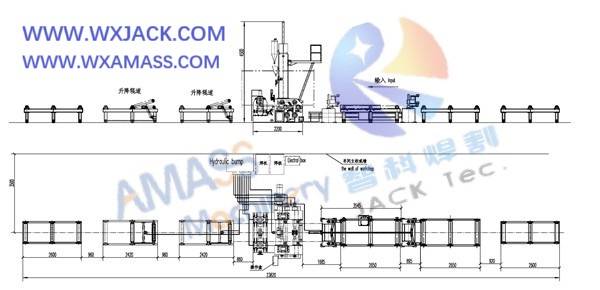

1. Layout Drawing of ZHJ8015 integral function SAW 3 in 1 H Beam Welding Line: (Fig.2)

As can be checked from the above layout print,

1) The working area of 3 in 1 H Beam Assembly Welding Straightening Machine has land occupation of 28m length by 7m width, which is only 30% that of H Beam Production Line;

2) Please check the production section of “PHJ ZHJ Compact 3 in 1 H Beam Assembly Welding Straightening Machine” on detailed analysis;

2. Input and Output Conveyor of 3 in 1 H Beam Assembly Welding Straightening Machine:

1) Material Flow Way: In the above layout drawing, the material flow is from right to left;

2) In the attached first photo, working parts flow is from inside screen from out of the screen. Or, in the 1st photo the conveyor we see is output conveyor of the 3 in 1 H Beam Welding Line;

3) Conveyor Style: As can be seen from the layout, there are 2~3 sets of manipulators deployed along the input conveyor of the 3 in 1 SAW H Beam Welding Machine, depending on length of workpiece;

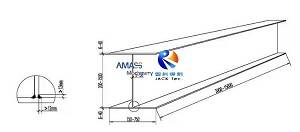

Input conveyor of Wuxi JACK ZHJ8015 model 3 in 1 SAW H Beam Welding Machine being deployed at customer facility: (Fig.3)

3. Hydraulic Drive Manipulators along Input Conveyor of 3 in 1 SAW H Beam Welding Machine:

1) Appearance: The attached 4th photo was taken on this oil cylinder drive manipulator (Pulling rod) and its installed conveyor;

2) Role and Function of the Hydraulic Manipulator for 3 in 1 H Beam Welding Line:

a) When the flange and web are hoisted onto the input conveyor of the 3 in 1 SAW H Beam Welding Machine, these strip plates need to be maintained to its expected orientation:

b) Flange in horizontal orientation, and web vertical orientation;

c) Both flanges and web should be aligned with centerline of the 3 in 1 H Beam Assembly Welding Straightening Machine mechanical main body. The hydraulic drive manipulator here plays this role;

Asembling flanges and web into H Beam in Wuxi JACK 3 in 1 H Beam Fabrication Machine: (Fig.4)

3. Mechanical Main Body of 3 in 1 H Beam Assembly Welding Straightening Machine:

1) Composition: The base bed (Shown in the attached 3rd photo) and inverted U gantry beam (Shown in the attached 5th photo) construct main body of the 3 in 1 SAW H Beam Welding Machine;

2) Importance: These 2 assemblies are the core parts of the 3 in 1 H Beam Welder, integrating the three working cells of assembling (Fine alignment for flange and web)/ SAW Welding / Flange straightening;

Mechanical base bed of Wuxi JACK 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.5)

Mechanical U frame gantry of Wuxi JACK 3 in 1 SAW H Beam Welding Machine: (Fig.6)

In the 3rd photo the closet to us is straightening section of the Vertical H Beam Welder:

Straightening unit of Wuxi JACK 3 in 1 H Beam Welding Line: (Fig.7)

4. Function and Welding Supporting Units in 3 in 1 SAW H Beam Welding Machine:

1) Back to the 2nd picture of 3 in 1 SAW H Beam Welding Machine layout;

2) It is suggested to locate the three function units of the vertical H Beam Welder: Control board/ Hydraulic pump station/ SAW power cell in a row, right next to the main body;

3) These working units need to be managed/ monitor during the entire working process of the Integral Function H Beam Welding Machine;

4) The welding supporting units in this 3 in 1 SAW H Beam Welding Machine, including wire feeding mechanism/ Welding flux sending and recovery/ Welding flux hopper, as can be seen in the 1st photo, are all installed and distributed on columns and overhead platform of 3 in 1 H Beam Welding Line main body;

Welding moment in Wuxi JACK 3 in 1 H Beam Welding Line: (Fig.8)

5. Ready for Work for 3 in 1 H Beam Assembly Welding Straightening Machine:

Finally, with the on position of all the units of the ZHJ series Integral Function H Beam Welding Machine, it will be put into use at customer site. As is shown in the attached 6th photo;

Workpieces from Integral Function H Beam Welding Machine: (Fig.9)

C. Technical Parameters of ZHJ8015 Model 3 in 1 H Beam Assembly Welding Straightening Machine:

Below are technical specifications of ZHJ8015 model SAW Integral Function H Beam Welding Machine (Vertical H Beam Welder):

Technical parameter | ZHJ8015 Automatic 3 in 1 H Beam Fabrication Machine |

Web | Height: 200 ∼ 1500 mm; Thickness: 6 ∼ 32 mm |

Flange | Width: 150 ∼ 750 mm; Thickness: 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3,000 ∼ 15,000 mm (Can be special made) |

Three-in-one Working Speed of Assembly/ Welding Straightening | Scope: 200∼1200 mm/min.(Stepless, Inverter Control, VFD Working Speed: 500~ 700 mm/min. |

Height of Single Pass Welding Seam | Max. 8~12 mm, flat fillet welding of SAW |

Workpiece | Welding H Beam/T Beam of Symmetric Section shape Only |

Overall Dimension(L×W×H) of ZHJ8015 3 in 1 H Beam Welding Line | 28m × 4m × 4.2m |

Input / Output Conveyor | 10~11m length each, 3 segments each; One segment with motor, two segments follower; Input conveyor has three pairs of fitting manipulators |

Driving Mode | Assembly/ Straightening: Hydraulic Cylinder Workpiece Traveling: A.C. motor |

Flange and Web Assembling | Hydraulic motor and cylinder automatically in-phase |

Welding Mode | SAW (Submerged Arc Welding), Single Arc or Twin Arc |

Welding Current | Working current : 380~ 750A; Up Limit: 1000 A |