1. Application of Z series Automatic H Beam Assembly Machine:

1) The first photo represents typical application site of I Beam Assembly and Tack Welding Machine: Highly automatic H Beam Production Line;

2) As you can find from the first photo, the other H Beam Production Machine following the H Beam Assembly Machine: 90° Steel Structure Overturning Rack, and LHC H Beam Submerged Arc Welding Machine. (Fig.1,2)

2. Manual versus Automatic CO2 Welding in Automatic I Beam Assembly Machine:

1) Advantage of Automatic CO2 Welding in H Beam Assembly Machine: (Fig.3)

a) For producing the same size of H Beam, Automatic I Beam Assembly and Tack Welding Machine has 15% higher price than that of Manual equipment;

b) Still, we recommend Automatic I Beam Assembling Machine to customer when they purchase this H Beam Production Machine, because of the below several reasons:

i. One set of Automatic H Beam Assembly Machine needs only one operator to take care production process, instead of two operators in the manual H Beam Assembly Machine;

ii. Requirement on operator capability in manual I Beam Assembly Machine is much more strict than operator of automatic equipment, in view of welding skill and experience;

iii. The H Beam Production Machine of Automatic H Beam Assembly Machine delivers finished H Beam with quality more stable and consistent than that of the manual equipment, so that less inspection work involved;

iv. More flexible in terms of control logic of the Automatic I Beam Assembly and Tack Welding Machine: For future expansion or update, because of PLC soft control, instead of hard wired relay circuit;

In this sense, the Automatic H Beam Assembly Machine can pay for itself more quickly than manual equipment;

2) Advantage of Manual CO2 Welding in H Beam Assembly Machine: (Fig.4)

a) Better utilization rate on CO2 welding power source: Customer can use the existing power sources of their own, instead of two sets of brand new as in the case of Automatic I Beam Assembling Machine;

b) If there exists problem with PLC program, one batch of unqualified H Beam may have already been produced, compared with possibly only one or two pieces in manual I Beam Assembly Machine;

c) This is the reason we suggest customer to have trial run in Single mode first before transferring to AUTO cycle, at initiation of H Beam Assembly Machine work.

3. Hydraulic System in I Beam Assembly and Tack Welding Machine:

1) Importance of Hydraulic System in H Beam Assembly Machine:

a) From the perspective of control and power, the Z15~Z20 H Beam Assembly Machine with Tack Welding is essentially controlled with electric PLC and inverter for its working logic and speed, and powered with hydraulic cylinder for its assembling job;

b) So, hydraulic system of the H Beam Production Machine I Beam Assembling Machine is of vital importance;

2) Composition of Hydraulic system in H Beam Assembly Machine: (Fig.5)

a) In H Beam Assembly Machine, hydraulic system is composed of pump station, cylinders and piping;

b) In Z15~Z20 H Beam Production Machine of I Beam Assembling Machine, downward pressing roller, web/ flange positioning and clamping unit, web/flange terminal alignment unit, pulling rod system, arc guiding unit are all controlled with hydraulic system;

c) Downward pressing roller, alignment unit and arc guiding unit are all started with hydraulic cylinder directly;

d) The hydraulic cylinder for driving the downward pressing roller has long stroke;

e) To cater for pressing down H Beam web of various specifications in the H Beam Assembly Machine, usually it is necessary to add an extension shaft at the front end of piston rod of the oil cylinder.

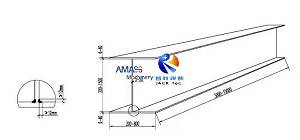

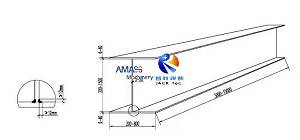

4. Technical Parameters of Z15~Z20 Automatic H Beam Assembly Machine:

Below are specifications of the H Beam Production Machine of Z15~Z20 Automatic I Beam Assembly Machine with Tack Welding:

Model | Z15~Z20 I Beam Assembly and Tack Welding Machine |

Max. H Beam Web Width | 1500/1800/2000 mm |

H Beam Web Thickness | 6∽32 mm |

H Beam Flange Width | 200∽800 mm |

H Beam Flange Thickness | 6∽40 mm |

H Beam Length | 4000∽12000 mm |

Max. H Beam Weight | 20 Ton. |

Hydraulic Motor Power | 4 kW |

Hydraulic Rated Pressure | 6 ~ 8 MPa |

Hydraulic Oil Pump Capacity | 24 L/min. |

Working Mode | Manual/Single/Auto |

Web and Flange Alignment Style | Self Alignment (Automatic) |

Tack Welding Style | Automatic CO2 tack welding |

CO2 Gas Shielded Welding Power Source | Panasonic KR350 or HUAYUAN NB350 |

Operator | 1 operator |

Assembly and Tack Welding speed (mm/min.) | 500 ~ 6000 |