A. The Nature and Specific Application of SXBJ-12 Special Made Sheet Metal Plate Edge Milling Machine:

1. Nature of the SXBJ-12 Special Made Sheet Metal Plate Edge Chamfering Machine:

1) The product name of this section implies primary characteristic of the SXBJ-12 Plate Edge Chamfering Equipment to be introduced here: It has two sets of edge milling units, and installed in symmetrical position along both sides of the steel plate Edge Chamfering Machine mechanical main body;

2) The small width strip plate to be edge beveled in SXBJ-12 Special Made Sheet Metal Plate End Milling Machine: (Fig.1)

2. Applicable Workpiece and Usage of SXBJ-12 Special Made Sheet Metal Plate Edge Chamfering Equipment:

1) Property: It is a Special Made Sheet Metal Plate Beveling Machine. The target workpieces to be processed are strip steel plates, which need to be edge milled for making welding groove on its both sides;

2) Applicable Workpieces: The prior equipment deployed before this special made Edge Milling Machine is CG4000 Strip Plate Cutting Machine, which cut steel plates into long slit strip plates of up to 12m length and 500~600mm width;

3) Applicating Example: One of the examples on the next equipment following the SXBJ-12 Edge Milling Machine is MP series Plate Butt Joint Welding Machine, which fabricates the edge beveled strip plates edge chamfered from the SXBJ-12 Edge Milling Machine, into semi-finished WIP (Working in Process) of larger steel plate, shown in below photo:

The flat butt joint steel plate which should be first edge grooved in SXBJ model Steel Plate Edge Milling Machine: (Fig.2)

4) Delivery: The chamfers/ Bevels/ Grooves made with the XBJ and SXBJ series Metal Plate Edge Milling Machine are top edge and or straight edge chamfers/ Bevels of designated styles;

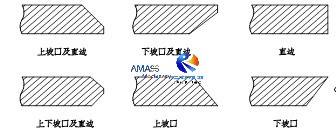

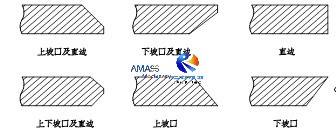

The upper and straight edges welding grooves that can be machined in XBJ model Sheet Metal Plate End Milling Machine: (Fig.3)

5) When should and how to make welding groove in the SXBJ-12 Special made Plate Beveling Machine?

a) Most of the times the workpieces do not need to have its bottom edges made into bevels, in the Sheet Metal Plate Edge Milling Machine. This is basically workpieces steel plate with thickness 15mm and less;

b) If it is does necessary to carry out edge milling on bottom edges of workpieces steel plate, the workpiece need to be taken off from the Edge Milling machine first, and then turned over 180°, making its original bottom edge into top edge, and put onto the Sheet Metal Plate End Milling Machine again, to implement the second time operation of metal plate beveling.

B. Maintenance and Lubrication of the SXBJ-12 Special Made Sheet Metal Plate End Milling Machine:

1. Working Environment and Points of Attention on Daily Operation and Maintenance of the SXBJ-12 Special Made Sheet Metal Plate Edge Milling Machine:

1) As can be found from the attached picture and below photo, this set of 12m stroke Special Made Sheet Metal Plate Edge Milling Machine is installed outdoors under a canopy, rather than inside indoors workshop. It is a matter of expediency and restricted by on site resources;

2) Operating surroundings of the SXBJ-12 Special Made Sheet Metal Plate Edge Chamfering Machine: (Fig.4)

3) Edge Milling Machine working under such environment is more prone to grow aging due to direct intrusion of wind and rain. For this reason, special care should be taken on daily operation and service of the Special Made Sheet Metal Plate Beveling Machine in such condition;

4) For this purpose, we provide detailed suggestion in the manual book of the XBJ and SXBJ series Edge Milling Machine for it’s the purpose of its proper maintenance. Customer can set up and implement strict TPM (Total Preventive Maintenance) plan and put it into practice based on practical condition;

2. Lubrication Plan and Implementation in the XBJ and SXBJ series Sheet Metal Plate Edge Milling Machine:

1) One of the main contents in maintenance of XBJ and SXBJ models Sheet Metal Plate Edge Chamfering Machine is lubrication, because such Edge Milling Machine has all its critical working units in high speed revolving during the process of metal plate beveling, including its Milling Head/ Leadscrew nut Couple and Worm Gear Reducer, etc.;

2) For fulfilling this task, we give detailed technical instruction on proper way of lubrication at the beginning of Edge Milling Machine put into work, and periodical lubrication in the long time use;

3) The Edge Milling Machine can maintain it’s the best status and the longest service time if these lubrication and maintenance to be carried out properly at customer site.

C. Technical Parameters of the SXBJ-12 Special Made Sheet Metal Plate Edge Milling Machine:

Below are technical parameters of this Symmetrically Arranged SXBJ-12 Double Heads Sheet Metal Plate Edge Chamfering Machine:

Model Technical Parameter | Symmetrically Arranged SXBJ-12 Double Heads Special Made Sheet Metal Plate End Milling Machine |

Metal Plate Max. Edge Milling Length Stroke and Width | 12,000 mm for length and 3,000 mm for width |

Plate Thickness Range for Performing Sheet Metal Edge Chamfering | 6∼50 mm (Based on customer demand) |

Quantity of Hydraulic Jacks for Pressing Steel Plate | 20 pieces |

Milling Angle Range of Top Milling Unit | 0° to +80° |

Milling Angle Range of Down Milling Unit | -45° to 0° |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Feeding Motor | 2.2 kW |

Milling Head Quantity | 2 sets |

Edge Milling Speed | 150∼1000 mm/min. VFD, Inverter Control |

Idle High Speed of Milling Head Carriage | Constant 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |