A. Usage of SXBJ-8 Double Heads Automatic Plate Edge Milling Machine:

1. The SXBJ-8 Double Heads Automatic Plate End Milling Machine is a custom made model, a set of medium large size Automatic Plate Edge Beveling Equipment, equipped with 2 sets of 7.5kW milling heads;

2. The SXBJ-8 Automatic Plate Edge Chamfering Machine is for machining welding groove on up and bottom edges of metal plate (Usually steel plate), into various common types, in the max. valid stroke of 8000mm;

3. During working period of the SXBJ-8 Automatic Plate Beveling Machine, the 2 sets of edge milling units can work on a piece of large workpiece together, for making top and bottom bevels with one time operation of stroke, or separately on two pieces/ two segments of individual sheet metal edge plate;

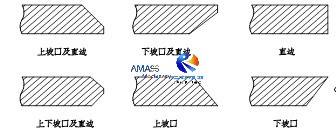

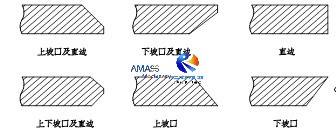

4. The most often seen welding grooves available for being produced in SXBJ-8 Automatic Plate Edge Beveling Equipment: (Fig.1)

5. The equipment with similar function as Edge Milling Machine are CG series Triple Flame Plate Cutting Machine, and GD20 Hobbing Cutter Shearing Machine. These equipment also are used for making bevels on metal plate, but work in different principle as the Edge Milling Machine.

B. Technical Brief on SXBJ-8 Double Heads Automatic Plate End Milling Machine:

1. Milling Head Equipped in Wuxi JACK Edge Milling Machine:

1) The milling head equipped in Wuxi JACK Automatic Plate Beveling Machine has high power 7.5kW, convenient operation, and stable performance;

2) Its spindle revolutionary linear velocity can be adjusted easily within 6 shifts;

3) The 7.5kW milling head installed in Wuxi JACK Automatic Plate Edge Chamfering Machine: (Fig.2)

2. Milling Units Horizontal Movement Guiderails in the Automatic Plate Edge Beveling Equipment:

1) During Edge Milling Machine work, the 2 sets of milling head carriages are guided with double tiers of horizontal guiderails;

2) Guiderails play important role in guaranteeing precise and stable running of the Sheet Metal Edge Milling Machine;

3) On the mechanical base bed of the Automatic Plate Edge Milling Machine, it is installed with top and bottom tiers of guide rails, for the purpose of guiding milling carriages traveling in the process of machining welding groove on edge of steel plate;

4) Of which the top rail is precise linear guideway, and the bottom rail is heavy duty type made of 45# steel, machined through the process of forging, normalizing, machining, and installed on the machine bed of Edge Milling Machine by means of bolt and pin;

5) The double tiers of milling head horizontal movement guiderails in Wuxi JACK Automatic Plate End Milling Machine: (Fig.3)

6) As can be seen from the above photo, the installation way of these double tiers of guideways on the Sheet Metal Edge Milling Machine is the combination of vertical hanging style and horizontal supporting style, giving the best degree protection on milling units of the Edge Milling Machine.

C. Maintenance of SXBJ-8 Automatic Plate Edge Milling Machine:

1. Proper maintenance of the XBJ and SXBJ series Plate Edge Milling Machine is very important for smooth running of this Edge Beveling Equipment;

2. Proper TPM (Total Preventive Maintenance) should be set up before put into use, and strictly implemented during its daily use;

3. For example, lubrication of critical transmission and moving units of the Edge Milling Machine:

1) The bottom tier guideway is lubricated automatically with self-lubricating bearing;

2) The top tier guideway needs to be lubricated manually through lubricating pump;

3) Handwheels, leadscrew and nut, as well as other transmission points should be lubricated every shift before official running of the Edge Milling Machine;

4) Lubricating pump in Wuxi JACK Automatic Plate Edge Milling Machine: (Fig.4)

4. We give suggestion on maintenance of this automatic Sheet Metal Edge Milling Machine in its manual book from the perspective of machine structure. Customer can integrate it into their TPM.

D. Technical Parameters of SXBJ-8 Automatic Plate Edge Milling Machine:

Below are specification of the SXBJ-8 Double Heads Automatic Plate Edge Chamfering Machine:

Model Technical parameter | SXBJ-8 Double Heads Automatic Plate Edge Milling Machine |

Max. Plate Beveling Length | 8,000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Plate thickness for Sheet Metal chamfering | 6∼50 mm |

Milling Angle of Top Milling unit | 0° to +80° |

Milling Angle of Down Milling unit | -45° to 0° |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jacks | 12 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |