1. The Application of RH1500 High Efficiency Edge Rounding Machine:

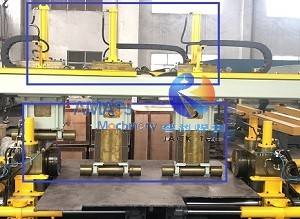

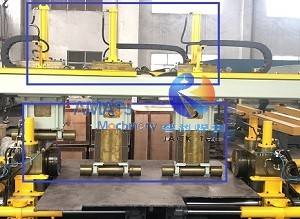

1) The attached pictures show a set of 1.5m width Edge Rounding machine for shipbuilding, in the process of assembly at Wuxi JACK workshop.

2) In this equipment, the working speed of 7200mm/min. rounding is really quick, which can help customer boosting their productivity in large degree. This is the reason we name the equipment RH1500 High Efficiency End Rounding machine. Please check below photo on working moment of the machine: (Fig.1)

2. The Four Critical Process Control Factors in Operation of RH series Edge Deburring and Rounding Machine:

For all the working units of the Edge Rounding machine, to attain the target of high quality and high speed deburring and rounding operation, below 4 factors need to be considered ahead of time:

1) Reasonable structure and configuration --- We have discussed this topic in the product section RH3000 Edge Rounding and Trimming machine;

2) Dimension of entire machine frame, assemblies, and components --- These are involved in specific design prints of all the models of RH series Edge Rounding machine;

3) Driving mode of each of the working step--- We will have an introduction on this topic in this product section of RH1500 High Efficiency End Plate Trimming machine;

4) Materials and Machining process of components in the machine--- We will have introduction on this topic in the product section of RH3000 High Precision Edge Rounding machine for shipyard.

3. Working Motions and its Driving Mode in RH1500 Edge Deburring and Rounding Machine:

In RH series End Plate Trimming machine, the rounding process on working parts, including steel plate, T Beam, and H Beam involves heavy force and delicate control. So, we adopt integrated driving solution of hydraulic, electric motor and pneumatic to fulfil the task:

1) Vertical adjustment of left and right rounding rollers based on varied workpiece thickness in End Rounding machine, is driven with 4 sets of oil cylinders (Left and right 2 sets each): (Fig.2)

2) Horizontal adjustment of left and right rounding rollers based on varied workpiece width, is driven with 4 sets of oil cylinders (Left and right 2 sets each): (Fig.3)

3) Horizontal inching adjustment on left and right rounding rollers for Edge Rounding machine workpiece slant side, is driven with another 2 pieces of oil cylinders, which is installed at left and right of Edge Rounding machine frame 1 set each;

4) Vertical adjustment of 3 pieces of downward stroke pressing rollers, to prevent the workpiece from being drummed up in the process of rounding, this is driven with 3 sets of oil cylinders at the overhead crossbeam of this automatic End Plate Trimming machine: (Fig.4)

In all, all the motions for positioning and securing of workpiece for the formal step of rounding, in this automatic Edge Rounding and Trimming machine are all hydraulic driving;

5) Input and output conveyor running, for feeding workpiece into, and sending out finished product out of the Edge Rounding machine, are driven with motor reducer: (Fig.5)

6) The 2 pieces of bottom rounding rollers revolving, fulfilling rounding operation in the Edge Rounding machine, is driven with the 2 sets of cycloidal motor reducer (Left and right side each): (Fig.6)

7) The 2 pieces of top rounding rollers revolving, fulfilling rounding operation: Idler, driven with the bottom rounding rollers, no external energy in the End Plate Trimming machine;

8) Scrap cleaning unit: This is pneumatic drive, installed at outlet of the main frame of the Edge Rounding machine;

In all, all the motions for deburring and rounding processing in this End Plate Trimming machine are driven with electric motor assisted with pneumatic system.

The above introduced working step driving way is also applied in smaller models of Edge Rounding machine, such as RH1000.

4. Technical Parameters of RH1500 High Efficiency Edge Rounding Machine:

Below are parameters of the RH1500 High Efficiency End Plate Trimming Machine:

| RH1500 Edge Deburring and Rounding Machine |

No. | Item | Parameter |

1 | Valid Working Parts Width | 150 ~ 1500 mm |

2 | Valid Working Parts Thickness | 10 ~ 40 mm |

3 | Valid Working Parts Length | 1000 ~ 12000 mm |

4 | Applicable H Beam Min Web Height | 320 mm |

5 | Rounding and Deburring Speed | 7200 mm/min |

6 | Rounding Radius | R2.5 mm |

7 | Main Rounding Rollers Diameter | φ300 mm |

8 | Power of Hydraulic Station | 4 kW |

9 | Max. Pressure in Hydraulic System | 12 MPa |

10 | Input and Output Conveyor Length | 10m each |

11 | Edge Rounding machine Total Power | 10.6 kW |

12 | Electricity Power Specification | 380V, 50 Hz, 3P |