1. General Introduction on RH1500 Plate Edge Rounding Machine:

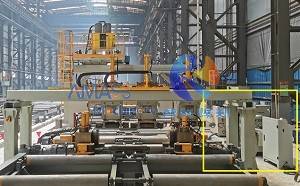

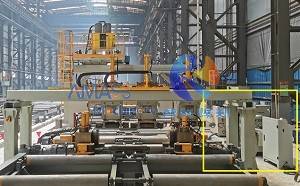

1) The attached first picture shows a set of RH1500 Plate Edge Rounding Deburring machine taken at a customer facility. You can identify its main frame, input and output conveyors;

2) As can be seen from the photo, together with other equipment, this set of middle sized Plate Edge Rounding machine constitute a production line for ship building;

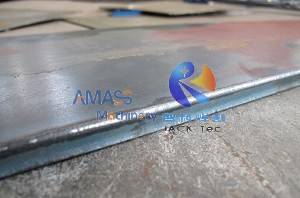

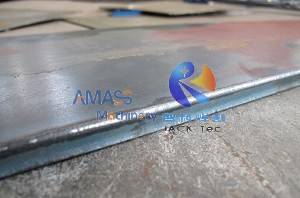

3) Effect of workpiece edge rounding and deburring from this Plate Edge Trimming machine please check below: (Fig.1)

2. Foundation of the RH1500 Plate Edge Deburring Machine:

1) Please check the attached pictures and below. For the Edge Rounding machine larger than 1m valid width (RH1000), the machine should be prepared for foundation: (Fig.2)

2) You may find from the photo that, foundation of the RH1500 Edge Rounding machine is made in a pit. Depth of this pit depends on the finished surface level of the conveyors: It should be flush with that of the remaining equipment in the production line;

3) After the pit dig, two times of cement pouring is the next step job during installation of the Plate Edge Rounding Deburring machine;

4) After curing period of the cement, anchor bolts are used for securing the Edge Rounding machine body into workshop floor pit;

5) The foundation of larger models of Edge Rounding machine: RH2000and RH3000, is prepared in the same way.

3. Layout of Main Units of RH1500 Plate Edge Rounding and Trimming Machine at Customer site:

1) Control Board of the Plate Edge Rounding Machine:

a) As you can check from the photos, it is put alongside the gantry frame body of the Edge Rounding Machine: (Fig.3)

b) For the purpose of convenient operation, this middle sized RH1500 Edge Rounding and Trimming machine has both operating panel on cover of the control board, and a remote pendant: (Fig.4)

c) The remote pendant is for the convenience of observing and adjusting rounding process close at hand;

2) Hydraulic Pump Station of the Plate Edge Rounding Machine:

a) This plate Edge Trimming machine is a kind of hydraulic driven equipment in real sense, because except conveyor running and transverse movement of rounding rollers, the other working operation of this Edge Rounding Deburring machine are all hydraulic driven. So, its working area is equipped with many pieces of oil cylinders: (Fig.5)

b) All the oil cylinders of this Plate Edge Rounding machine are controlled with corresponding electromagnetic valves of hydraulic system;

c) The oil pump station giving power to all oil cylinders by means of electromagnetic valves, is also put alongside main frame of the Plate Edge Deburring machine, adjacent to the control board.

4. Cables, Pipeline and Tubes Routing of RH1500 Plate Edge Rounding Machine:

1) As introduced before, this Plate Edge Rounding Deburring machine integrates electric motor drive, hydraulic drive, and pneumatic drive into one equipment for all its tasks;

2) Consequently, there are numerous lines of cables, oil pipelines, and gas tubes deployed all the way in this complicated Edge Trimming machine;

3) To have proper routing of these lines is very important for safe operation, effective service, and good appearance of the whole set of this Plate Edge Rounding and Trimming machine;

4) As can be checked from the attached pictures, the “artery” and “vein” of the Edge Rounding machine are deployed in the ingenious combined way of drag chain, overhead beam, cable bridge, clips and tunnels, attaining a plain and reasonable arrangement of the lines, making sure consistent and reliable delivery of the Edge Rounding machine at customer site: (Fig.6)

5. Technical Parameters of RH1500 Plate Edge Rounding Machine:

Below are parameters of this RH1500 Edge Rounding and Trimming Machine:

| RH1500 Plate Edge Rounding Deburring Machine |

No. | Item | Parameter |

1 | Fitting Workpiece Width Range | 150 ~ 1500 mm |

2 | Fitting Workpiece Thickness Range | 10 ~ 40 mm |

3 | Fitting Workpiece Length Range | 1000 ~ 12000 mm |

4 | Suitable H Beam Min. Web Height | 320 mm |

5 | Rounding and Trimming Speed | 7200 mm/min. |

6 | Finished Rounding Radius | R2.5 mm |

7 | Main Rounding Rollers Diameter | φ300 mm |

8 | Hydraulic Station Power | 4 kW |

9 | Max. Pressure of Hydraulic System | 12 MPa |

10 | Input and Output Conveyor Length | 10m each |

11 | Total Power of Edge Rounding machine | 10.6 kW |

12 | Power Specification | 380V, 50Hz, 3P |