A. The Finished Product of PHJ and ZHJ series Integral Function H Beam Assembly Welding Straightening 3 in 1 Machine:

1. In Steel Structure Industry, there are 2 kinds of H Beam: Hot rolled and welding type;

2. The welding H Beam has larger dimensions and broader application than hot roller H Beam. Correspondingly, Steel Structure H Beam Machine has very extensive use in Steel Structure facilities worldwide: It is necessary equipment at every plant;

3. Taking the position of traditional H Beam Production Line for producing light to medium duty welding H Beam, the PHJ and ZHJ series H Beam Assembly Welding Straightening 3 in 1 Machine is for automatically producing welding H Beam in various sizes, with the strong points of: High quality, high productivity and low cost;

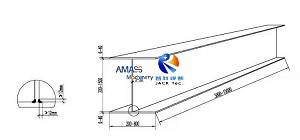

1) Sketch of Welding H Beam produced from Integral Function H Beam 3 in 1 Fabrication Machine: (Fig.1)

2) Welding H Beam produced from Wuxi JACK 3 in 1 Function Steel Structure H Beam Machine: (Fig.2)

B. Benefits of PHJ and ZHJ Series Integral Function H Beam 3 in 1 Fabrication Machine:

1. The 3 General Steps: To manufacture finished H Beam from steel strip plates, the raw materials need to go through 3 general steps of: Assembly, Welding and Straightening. The traditional H Beam Production Line has 3 types of equipment for completing these 3 steps;

2. From 3 Machine to 1: Comparatively, the PHJ and ZHJ model H Beam 3 in 1 Fabrication Machine integrates the 3 functions into one equipment, which provides huge profit for Steel Structure customers on saving investment and raising productivity. This is the reason that, why this new generation Steel Structure H Beam Machine is also named as 3 in 1 Vertical H Beam Welder, or 3 in 1 H Beam Welding Machine;

3. Remove Transferring Equipment: Besides, in traditional H Beam Production Line, there should be internal logistics unit among the 3 machines for WIP (Work in process) flipping and transfer. Now, with the use of Integral Function H Beam 3 in 1 Fabrication Machine, the traditional H Beam Production Line is “Concentrated” into an individual equipment of 3 in 1 H Beam Welding Machine.

C. Process Technology of PHJ and ZHJ Series 3 in 1 Function Steel Structure H Beam Machine:

Below is the typical process routed realized inside this 3 in 1 H Beam Welding Machine:

1. Assembling: From Raw Material Plates to Flange and Web in 3 in 1 Vertical H Beam Welder:

1) 2 piece of long narrow steel plates which are served as flange and web of H Beam are sent to H Beam 3 in 1 Fabrication Machine;

2) The Assembly unit is deployed at input conveyor and incoming side of central working area, in H Beam Assembly Welding Straightening 3 in 1 Machine;

3) The assembling is performed with 2 steps: The first step for rough positioning and clamping of the web and flange is completed with three sets of pulling rod system arranged alongside the input conveyor:

Pulling rod system of the 3 in 1 Vertical H Beam Welder: (Fig.3)

4) The second step for precise final positioning and alignment of the web and flange is fulfilled with 6 groups of alignment rollers, which are arranged in mirror at the incoming side central area of the H Beam Assembly Welding Straightening 3 in 1 Machine;

Alignment Rollers of the 3 in 1 H Beam Welding Machine: (Fig.4)

2. H Beam CO2 or SAW Welding in the PHJ and ZHJ 3 in 1 H Beam Welding Machine:

There are 2 types of welding mode in 3 in 1 Function Steel Structure H Beam Machine:

1) Most majority is in SAW- Submerged arc welding, which accounts for over 90% of practical use, for welding small to medium duty H Beam;

2) Minority condition of the 3 in 1 H Beam Welding Machine utilizes GMAW CO2 welding, which sees its application less than 10%, for producing welding H Beam with web thickness around 6~ 10mm;

3) Sometimes, to have full utilization of the H Beam 3 in 1 Fabrication Machine, even the models adopting GMAW CO2 welding is equipped with SAW power supply;

4) In PHJ and ZHJ series 3 in 1 Function Steel Structure H Beam Machine, welding is implemented with 2 sets of power supply, together with 2 sets of welding system: The welding torch, wire feeder, control panel and flux recovery unit:

Welding system in work, of the H Beam Assembly Welding Straightening 3 in 1 Machine: (Fig.5)

3. Flange Straightening in PHJ and ZHJ 3 in 1 Function Steel Structure H Beam Machine:

1) H Beam Flange usually generate deformation after welding caused of heat input effect;

2) The PHJ and ZHJ series H Beam 3 in 1 Fabrication Machine has its straightening unit deployed at outlet side of central zone, to make the flange straightened;

3) Flange straightening operation is done with hydraulic drive. The critical elements are 3 pieces of heavy force solid type straightening rollers, the top larger one with downward stroke working mode;

Straightening system in operation, of the 3 in 1 Function Steel Structure H Beam Machine: (Fig.6)

D. Technical Parameters of PHJ and ZHJ series H Beam Assembly Welding Straightening 3 in 1 Machine:

Below are workpiece specifications and main parameters of PHJ/ZHJ series H Beam 3 in 1 Fabrication Machine:

Technical parameter | PHJ15 | PHJ18 | PHJ20 | ZHJ8015 | ZHJ8018 | ZHJ8020 |

| 3 in 1 Function Steel Structure H Beam Machine |

Web height | 200∼1500mm | 200∼1800mm | 200∼2000mm | 200∼1500mm | 200∼1800mm | 200∼2000mm |

Web thickness | 5∼30 mm | 6∼32 mm |

Flange width | 200∼800 mm | 150∼750 mm |

Cross Section Style | Symmetric and Asymmetric all available | Symmetric Only |

Assembling | Semi automatic: One side oil cylinder drive, the other side manual leadscrew | Automatic: Both sides oil cylinders drive |

Flange thickness | 6∼40 mm |

H Beam length | 3000∼15000 mm |

Welding Mode | SAW, or GMAW |

Single Pass Welding Seam Height | 8 ~ 12 mm |

Straightening Mode | Hydraulic oil cylinder drive downward stroke |

Working Speed (Assembly, Welding and Straighten Integrated) | 200∼1200mm/min.(VFD) |

Machine size(L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |