The first photo was taken on a set of LHA4Z gantry structure Automatic H Beam Submerged Arc Welding Machine put into use at customer site.

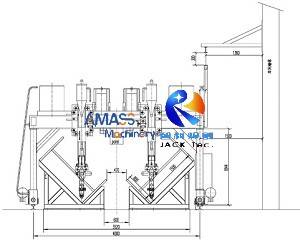

1. Working Capability of LHA4Z Gantry Structure Automatic H Beam Welding Machine and Comparison with LHA4C H Beam Welding Machine: (Fig.1)

1) Working Capability of LHA4Z I Beam Gantry Welding Machine:

a) As explained in the product section of “LHT T type H Beam Submerged Arc Welding Machine”, LHAZ stands for center control I Beam Gantry Welding Machine in Chinese language;

b) And the figure “4” in its model implicates that this H Beam SAW Machine has 4m gantry span (Or rail span). This is the smallest model in LHA series Automatic I Beam Gantry Welding Machine, producing welding H Beam with its web height up to 1200mm;

2) Comparison with LHA4C H Beam Welding Machine:

a) On the contrary, for side control style gantry structure H Beam Welding Machine, the counterpart of LHA4C with the same dimension of 4m gantry span, the delivered welding H Beam can have its web height up to 1500mm;

b) In this respect, for center control gantry style I Beam Submerged Arc Welding Machine, it sacrifices size of welded H Beam to make up for ease of operation --- one less operator in LHA4Z center control H Beam automatic Welding Machine compared with LHAC side control automatic H Beam Welding Machine

c) For this reason, the LHAZ series center control Automatic H Beam Submerged Arc Welding Machine sees more application than LHAC side control H Beam Welding Machine nowadays, suppose customers produce medium small sizes of welding H Beam.

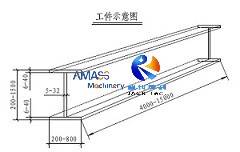

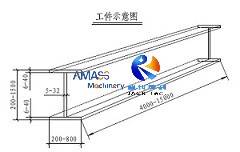

2. Brief on Operating Process of Automatic LHA Series I Beam Gantry Welding Machine: (Fig.2)

1) Because each piece of H Beam has four pieces of seams waiting to be welded, so the LHAZ H Beam Welding Machine needs to perform four times of SAW (Submerged Arc Welding) on the H Beam. And because this structure of Automatic H Beam Submerged Arc Welding Machine has two welding stations in one equipment, each time it can weld two pieces of H Beam together at the same time;

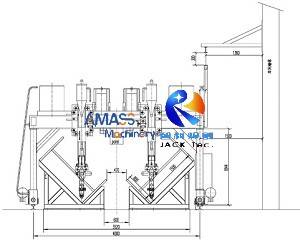

2) To fulfil the SAW on the abovementioned four seams of welding H Beam, this set of LHA4Z Automatic H Beam Welding Machine needs to travel back and forth four times in a row along its rail: (Fig.3)

a) Weld the first piece of seam. Along this stroke the gantry traveling speed of the H Beam SAW Machine is adjustable welding speed;

b) At the completion of the first piece of seam welding, the gantry moves backward to its original starting point in quick idle speed;

c) The H Beam is turned 90° by means of traveling crane or other flipping equipment, to 45° fillet welding position of the another welding seam of H Beam, on workpiece rack of the LHA4Z Automatic I Beam Gantry Welding Machine;

d) The Automatic H Beam Welding Machine performs the second piece of seam welding same as the first piece of welding seam mentioned as above;

e) At the completion of the second piece of seam welding, the gantry of the H Beam SAW Machine goes back to its starting point again in high idle speed;

f) The H Beam is flipped to welding position of it’s the third seam as the step of No. C;

g) The same SAW process is implemented for the third and fourth seams of the H Beam in this LHA4Z Automatic I Beam Gantry Welding Machine;

3) For each piece of SAW seam on the H Beam, the working process of this Automatic H Beam Submerged Arc Welding Machine is:

a) With the help of traveling crane, hoist H Beam onto its supporting rack, or change welding position of the H Beam on the rack--- To the ideal position of 45° fillet welding;

b) Adjust mechanical seam tracing unit of the Automatic H Beam Welding Machine;

c) Start on welding power supply equipped with the LHA4Z H Beam SAW Machine.

3. Technical Parameters of LHA4Z Automatic H Beam Welding Machine:

Below are specifications of LHA4Z Center Control Automatic I Beam Gantry Welding Machine:

LHA4Z Gantry Structure Automatic H Beam Submerged Arc Welding Machine |

Parameter | Specification | Note |

Operator Working Position | Center of Gantry, between two supporting racks |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 1200 |

|

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 |

|

Gantry Span (mm) | 4000 |

|

Gantry Travel Rail Length (mm) | 18000 |

|