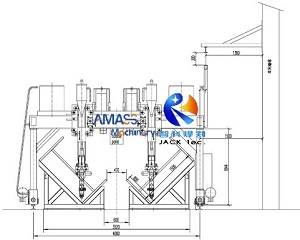

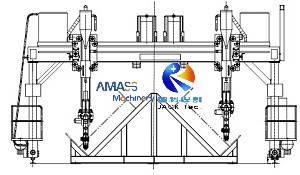

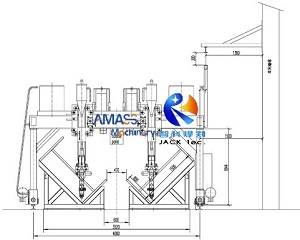

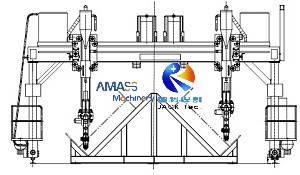

There are variations in specific structure and size of LHA series Gantry H Beam Welding Machine in practical use. The attached photos indicated several of typical models of its kind. For sketch on two main types of its structure applied in LHA H Beam Submerged Arc Welding Machine, please check below: (Fig.1)

1. SAW Power Supply in Various types of Gantry H Beam Welding Machine:

1) As introduced in product category of H Beam Submerged Arc Welding Machine, H Beam SAW Machine is the core H Beam Production Machine in the manufacturing process of welding H Beam, which affects quality of the H Beam produced to the greatest extent;

2) For this reason, the SAW power source we outsource for LHA series automatic I Beam Gantry Welding Machine (I Beam is the same name as H Beam), as well as LHC column type H Beam Welding Machine and LHT T type Gantry H Beam SAW Machine, is of the top notch in the welding equipment industry;

3) With years of testing and validation, we recommend two options on SAW power source to be used in product group of H Beam Welding Machine:

a) Chinese Brand HUAYUAN ZD7-1000: (Fig.2)

b) U.S. Brand Lincoln DC1000 (Fig.3)

4) Of which the Chinese HUAYUAN has very good cost performance. It is stable and consistent in delivering high standard of welding quality, with reasonable equipment price. Nowadays, HUAYUAN is one of the main brand SAW power supplies that are equipped in the LHA series Gantry H Beam Submerged Arc Welding Machine.

2. Introduction on SAW Power Supply in H Beam Submerged Arc Welding Machine:

1) Function of the SAW Power Supply in H Beam SAW Machine:

a) ZD7 series inverter control integrated function power source can be used in diversified welding mode, including automatic submerged arc welding, electroslag welding, sticking welding and arc air gouging;

b) Besides, this power supply also has very satisfactory delivery on DC single wire welding and strip surfacing;

2) Technical Characteristic of the SAW Power Supply in LHA I Beam Gantry Welding Machine:

a) The main control circuit of this ZD7 SAW power source is of IGBT inverter circuit. It has strong points of superior dependability, quick reaction time, and consummate dynamic characteristic;

b) The ZD7 SAW power source has capability of compensating automatically against potential risk of grid voltage fluctuation, making sure stable and consistent arc burning during SAW of the LHA Gantry H Beam Welding Machine, as well as guaranteeing good appearance and high intensity welding seam generated;

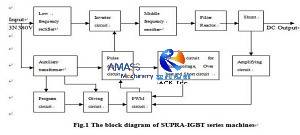

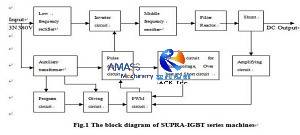

3) Working Principle of the SAW Power Supply in Gantry H Beam Welding Machine:

ZD7 series inverter control integrated capability welding power supply utilizes inverter main circuit as its control loop, as shown below: (Fig.4)

a) During SAW implementation in the Gantry H Beam SAW Machine, the three phase A.C. power from workshop utility is converted to 20KHz high frequency D.C. current, after being rectified through three phase rectifiers;

b) By means of the IGBT inverter, this high frequency D.C. current will be inverted to A.C. high frequency current as transition;

c) Following that, this inverted A.C. high frequency current will be rectified back to D.C. current again: With the continuous going through voltage diminishment in the high frequency transformer, the A.C. current is rectified to D.C. type back again;

d) This D.C. current is then filtered through reaction loop, and controlled by the signal from the current negative feedback;

e) After being amplified, this negative feedback signal is fed into the inverting interface of the error amplifier, and running through the pulse width adjusting integrated circuit;

f) By this time, this amplified signal can control the working time of IGBT, and hence inverter rectifier can get the required external characteristic, for getting the expected performance of the LHA Gantry H Beam Welding Machine;

4) For control console of the SAW power source used in the LHA H Beam Submerged Arc Welding Machine,please check attached picture and below: (Fig.5)

3. Technical Parameters of LHA series Gantry H Beam Welding Machine:

Below are specifications of this LHA High Quality I Beam Gantry Welding Machine (Gantry H Beam SAW Machine):

LHA Series Gantry H Beam Submerged Arc Welding Machine |

Parameter | Specification | Note |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 1200/1500/1800/2000 | Varies on models |

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Submerged Arc Welding type | 45° fillet welding |

|

Submerged Arc Welding mode | Single Arc, Or Tandem Arc |

|

Welding Power Source brand | Chinese HUAYUAN or U.S.A Lincoln | ZD7-1000 or DC-1000 |

Welding Power Source quantity | 2 sets in the case of Single Arc, And 4 sets in the case of Tandem Arc | Machine quotation is different as in the case of Single Arc and Tandem Arc |