Specialty of Table structure CNC Plasma Cutting Machine:

1) From the first photo on the CGT1500 CNC Plate Cutting Machine, you can identify the difference between gantry type CNC Plasma Cutting Machine and Table type CNC Plasma Plate Cutting Machine at first glance;

2) In this section we will have a short discussion on this small division in the product family of CNC Strip Plate Cutting Machine.

A. Disparity of Table Structure CNC Plasma Plate Cutting Machine against Gantry type CNC Plasma Cutting Machine:

1) Motor drive moving gantry structure is undoubtedly the mainstream design in CNC Strip Plate Cutting Machine, for no matter implementing flame cutting and plasma cutting;

2) In technical view, the uniqueness of Table type CNC Plasma Cutting Machine lies in:

1. Mechanical Main Body of the Table type CNC Plate Cutting Machine:

1) It is of compact and integral box structure, firm and durable. Meanwhile, overall dimension of the CNC Plate Cutting Machine main body is much smaller:

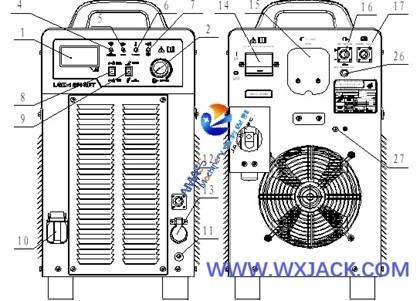

Mechanical main body of Table structure CNC Plasma Plate Cutting Machine: (Fig.1)

2) For standard specification of CNC Plasma Plate Cutting Machine, there are two grades of:

width (1,500mm and 1,800mm) mated with two grades of length (3,000mm and 5,000mm) respectively, hence totally four grades of CNC Plate Cutting Machine size :

1. 1,500mm Width x 3,000mm Length;

2. 1,500mm Width x 5,000mm Length;

3. 1,800mm Width x 3,000mm Length;

4. 1,800mm Width x 5,000mm Length

In Table structure CNC Plasma Cutting Machine;

2. Configuration of the Table Structure CNC Plasma Cutting Machine:

1) Quantity of Plasma Cutting System in CNC Plasma Cutting Machine:

Unlike gantry structure CNC Strip Plate Cutting Machine, of which more than one cutting torch is not uncommon, in table type CNC Plasma Cutting Machine, due to its small size, generally it is equipped with one set of plasma cutting system only:

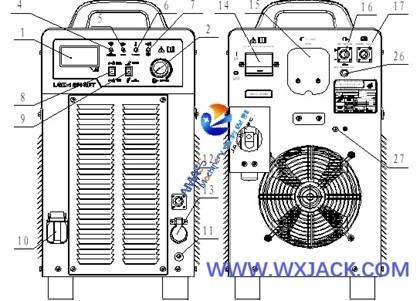

Plasma cutting system in CNC Plasma Cutting Machine: (Fig.2)

3. Technical Characteristics of Plasma Cutting System in the CNC Plasma Cutting Machine:

1) Applicable workpiece specifications: Also, unlike gantry structure CNC Plasma Cutting Machine, which can be equipped with any models of plasma power supply, from cutting thin material of small current output, to cutting thick material of large current output, in Table type CNC Plasma Plate Cutting Machine, the CNC Plate Cutting Machine is generally applicable for being equipped with small medium specification only:

Plasma power supply in CNC Plasma Plate Cutting Machine: (Fig.3)

2) Applicable plasma cutting style: Besides, taking advantage of its super stable structure of mechanical structure, the Table structure CNC Plasma Plate Cutting Machine is very suitable for working with fine plasma cutting system;

4. Mechanical Structure of Table type CNC Plasma Cutting Machine:

1) Assembly style: The third disparity with Table structure CNC Plasma Cutting Machine is, in gantry structure CNC Plasma Cutting Machine, the three major mechanical systems of horizontal traveling beam/ Longitudinal traveling parallel cutting rail/ Cutting platform are individual ones, which are separated from each other;

b) Superiority: Comparatively, in table type CNC Plasma Cutting Machine, these units are incorporated into one entity. This is the basic reason why Table structure CNC Plasma Plate Cutting Machine has the highest degree of running stability in product family of CNC Strip Plate Cutting Machine, and hence the meaning of its existence, which we will have an explore in next segment;

c) Specifications: This is also the reason that, in table type CNC Plasma Plate Cutting Machine, machine size is close to valid cutting size, only in slightly larger dimension. For example, here in CGT1500, the model refers to 1,500mm valid cutting width, and the corresponding worktable width is 1,600mm.

B. Application of Table Structure CNC Plasma Plate Cutting Machine:

Getting to know its special points and advantages, we can come to conclusion on applicating field of Table structure CNC Plasma Cutting Machine:

1. Not for: Such compact and high precision CNC Plasma Cutting Machine is not suitable for being used in large scale and relatively extensive working site such as Steel Structure/ Infrastructure project;

2. But for: Instead, the Table type CNC Plasma Plate Cutting Machine is “born” to be applied in delicate application scenarios, especially for cutting small size and thin (plus and or minus 10mm thickness) stainless steel, Al, etc.

3. Supplementary notes: For introduction on the “mainstream” structure of gantry type CNC Plasma Cutting Machine, please check product section of “Multi Cutting Capacity CG4000 Double Drive CNC Plasma Cutting Machine”.

C. Technical Parameters of Table structure CNC Plasma Cutting Machine:

Below are technical parameters for this CGT1500 Table type CNC Plasma Plate Cutting Machine

(CNC Plate Cutting Machine):

CGT1500 Table Structure CNC Plasma Plate Cutting Machine (CNC Plasma Cutting Machine) |

Cutting Worktable Width | 1600 mm |

Max. Work Piece Width | 1500 mm |

Cutting Worktable Length | 3200/ 5200 mm |

Max. Work Piece Length | 3000 / 5000 mm |

Drive for Cutting Torch Movement | Double Servo Drive |

Applicable Cutting Way | Plasma Plate Cutting |

Quantity of CNC Plasma Cutting Torches | Suggestion is 1 set |

Min. to Max. Quality Plasma Cutting Thickness | 0.3 mm ~ 22 mm (Suggestion) |

Min. to Max. Plasma Cutting Speed | 1000 ~ 3000 mm/ min. (Inversed with cutting thickness) |

Plasma Cutting Precision | ±0.5mm/1000mm |

Positioning Precision of Plasma Cutting Torch | ±0.25 mm |

Repetitive Positioning Precision | ±0.2 mm |