A. Usage of 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1. Other Frequently Used Names of the Welding H Beam Fabrication Machine:

1) 3 in 1 H Beam Assembly Weld Straighten Integral Machine;

2) Fit Up Full H Beam Fabrication Machine;

3) Fit Up Full I Beam Fabrication Machine

4) 3 in 1 H Beam Welding Machine;

5) Integral function H Beam Welding Machine;

2. Application of 3 in 1 H Beam Welding Machine:

1) Function: This is new generation automatic welding H Beam production machine, with advanced technique and user friendly operation;

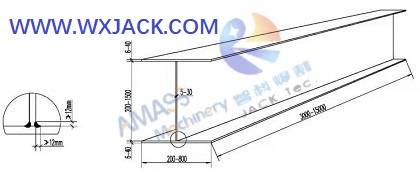

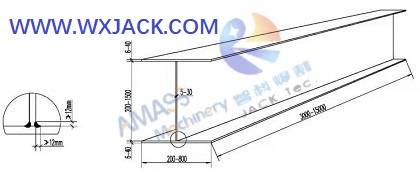

2) Output: Fit Up Full H Beam Fabrication Machine produces welding T/ I / H Beams with web height from 200mm to 2000mm, welding toe from 6mm to 12mm, the basic working parts applied in Steel Structure construction projects;

3) Design sketch on welding I/ H Beam from Fit Up Full I Beam Fabrication Machine: (Fig.1)

4) Welding T/ H Beams produced from Wuxi JACK Integral function H Beam Welding Machine: (Fig.2,3)

B. Advantages of Wuxi JACK Fit Up Full H Beam Fabrication Machine:

1. One Machine Equals Three with 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

This machine integrates functions of original 3 central machines in H Beam Production Line:

1) H Beam Assembly and Tack Welding Machine;

2) H Beam Submerged Arc Welding Machine;

3) H Beam Flange Straightening Machine;

Into single set of equipment;

2. Huge Financial Benefits of Welding H Beam Fabrication Machine:

In this way, in the field of light to medium duty welding T/ I/ H Beam manufacture, 3 in 1 I Beam Fabrication Machine can save budget for customers in quantitative data:

1) Over 50% machine investment;

2) Over 60% land and utility period cost;

3) Over 60% manual labor;

4) Over 60% variable cost of daily operation, including electricity/ maintenance/ consumables, etc.;

5) Remove internal logistics unit among the original 3 sets of the machines.

C. Competitive Edges of Wuxi JACK 3 in 1 H Beam Welding Machine:

1) The Earliest Development: PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Integral machine is superior product of our company. In 2009, Wuxi JACK is the 1st company in industry to upgrade I H Beam Fabrication Machine from concept design to practical use, and put into market;

2) Top Grade Technique: 3 in 1 I Beam Fabrication Machine developed by Wuxi JACK has overall technical superiorities compared with other supplier’s products, covering the 3 central functions of assembly/ welding/ straightening. For detail, please check product page of H Beam Fabrication Machine;

3) Leading Market Share: Over the past 2 decades, Wuxi JACK powerful 3 in 1 H Beam Welding Machine is widely welcomed by customers both in China and overseas, especially Russia, Central Asia, Southeast Asia, South America.

D. Classification on Wuxi JACK 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1. Two Series of 3 in 1 I Beam Fabrication Machine:

PHJ series and ZHJ series:

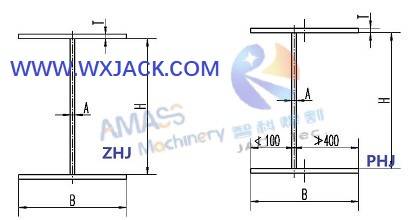

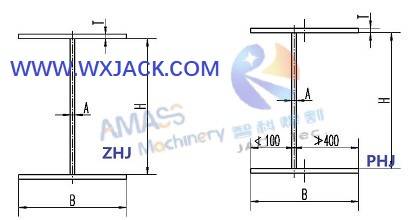

1) Which differs on flange and web fitting up manner, and hence cross section style of finished T/ I/ H Beam;

2) H Beam cross section from PHJ and ZHJ Integral Function H Beam Welding Machine: (Fig.4)

2. ZHJ series 3 in 1 Fit Up Full H Beam Fabrication Machine:

1) Focuses on producing symmetric cross section welding T/ I/ H Beam;

2) A set of Wuxi JACK ZHJ15 Fit Up Full I Beam Fabrication Machine fabricates vertical equal lateral length H Beam: (Fig.5)

3. PHJ Series 3 in 1 H Beam Welding Machine:

Manufactures welding T/ I/ H Beam with both equal and unequal length flange.

E. Technical Characteristics of Wuxi JACK Fit Up Full I Beam Fabrication Machine:

1. Assembly Unit in Fit Up Full H Beam Fabrication Machine:

1) PHJ series works in semi-automatic mode: One side of workpiece is driven with hydraulic oil cylinder, and the other side is adjusted manually with handwheel turning;

2) ZHJ series works in automatic mode, both sides fitting up are driven with hydraulic oil cylinder;

3) Both PHJ and ZHJ Fit Up Full H Beam Fabrication Machine assembling positioning are guided with precise bushing, aligned with eccentric roller, guaranteeing accurate fitting up flanges with web;

4) Comparison on Assembling Pressing Rollers of Wuxi JACK and Other Supplier produced Fit Up Full H Beam Fabrication Machine: (Fig.6, 7)

2. Welding Unit in Integral Function H Beam Welding Machine:

1) SAW (Submerged arc welding) takes majority welding job, fabricating 6mm ~ 40mm flange thickness;

2) CO2 Welding: This is featured configuration of Wuxi JACK Integral Function H Beam Welding Machine, for fabricating super light T/ I/ H Beams, with flange thickness 3mm ~ 12mm;

3) Comparison on Welding Torch Position Control Unit in Wuxi JACK and other supplier’s 3 in 1 H Beam Welding Machine: (Fig.8,9)

3. Straightening Unit in 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1) 2 Times Capacity: Wuxi JACK H Beam Fabrication Machine has 2 times straightening capacity than that of other suppliers:

2) To be specific, Wuxi JACK max. straightening capability is 40mm flange thickness for Q235 carbon steel (Tensile strength 370~ 510 MPa), or 30mm flange thickness for Q345 carbon steel (Tensile strength 510 ~ 600 MPa);

3) Other supplier max. straightening capability is only 20mm flange thickness for Q235 carbon steel. Can not straighten Q345 carbon steel;

F. Technical Parameters of Wuxi JACK Integral Function H Beam Welding Machine:

1) Below are parameters of standard models PHJ and ZHJ series 3 in 1 H Beam Welding Machine;

2) We also design and produce special specifications based on customer requirement.

| 3 in 1 H Beam Assembly Welding Straightening Integral Machine (3 in 1 H Beam Fabrication Machine)

|

Technical Parameter | PHJ15 | PHJ18 | PHJ20 | ZHJ8015 | ZHJ8018 | ZHJ8020 |

Web Height | 200∼1500 mm | 200∼1800 mm | 200∼2000 mm | 200∼1500 mm | 200∼1800 mm | 200∼2000 mm |

Web Thickness | 5∼30 mm | 6∼32 mm |

Flange Width | 200∼800 mm | 150∼750 mm |

Flange Thickness | 6∼40 mm |

Single Pass Welding Seam Height | 8~12 mm |

Workpiece Length | 3000∼15000 mm |

Welding Speed (Assembly, Straighten same) | 200∼1200 mm/min.(VFD) |

Machine Size(L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |