Operator Friendly ZHJ8015 Model Integral Function I H Beam Welding Machine:

1) Subject: Every photo of this production section has operator working on the Vertical H Beam Welder ---

Yes, this is the focus of attention we will have in this product section of the ZHJ series Integral Function I H Beam Welding Equipment;

2) Together with the relationship between operator and this 3 in 1 I H T Beam Welding Machine.

A. How does People Interact with ZHJ Model Integral Function I H Beam Welding Machine?

1. People Expectation on Operating the 3 in 1 I H Beam Fabrication Machine:

1) Purpose: In essence, machine serves people. No matter in view of delivering finished product for the convenience of human life, or in view of making people skilled and valuable;

2) Operator qualification and goal: As an operator of the ZHJ series 3 in 1 I H Beam Welding Machine, he or she should be familiar with structure/ performance/ operation and common trouble shooting on this Vertical I H Beam Welder, grasping knowledge on SAW (Submerged arc welding) technique, strictly abide by safety regulation of workshop, and with time going, grow from novice to veteran;

2. Expectation on Running of 3 in 1 H Beam Fabrication Machine:

Wuxi JACK Aim: This ZHJ series Automatic Integral Function I H Beam Welding Equipment should be a well established quality product of consistent and reliable work performance, complete function, and high quality workmanship, which is the duty of Wuxi JACK;

3. Tasks of Operator: The operating duty on ZHJ series Integral Function I H Beam Welding Machine (H Beam Fabrication Machine) covers Daily Operation/ Service/ Supervisory Control of the Vertical I H Beam Welder, which should be stipulated in TPM (Total Preventive Maintenance);

4. In all, the principle of “Action and reaction” tell us, that the more careful you take on the management on daily operation of the Integral Function I H Beam Welding Equipment, the better and more return you get.

B. Routine Operation of the ZHJ Series Integral Function T Beam Welding Machine:

1. Content of Job from the 3 in 1 I H Beam Welding Equipment:

This is a set of automatic and user friendly equipment of ZHJ8015 Automatic Integral Function I H Beam Welding Machine. The main duty of operator has 3 sections of:

1) Manual loading and unloading of raw materials and finished T I H Beam (Flange and web cut from CNC Strip Plate Cutting Machine); working in process of T Beam; And finished product of H Beam/ I Beam to and from the 3 in 1 I H T Beam Welding Machine;

2) Before working, set up series of process control parameters involving process steps of the Vertical I H Beam Welder, by means of manipulating on operating panel and control console of the H Beam Welding Machine and SAW power supply;

3) Observe on working process of the ZHJ models Integral Function I H Beam Welding Equipment, and if necessary, make adjustment, as is shown in the attached photos;

2. For structure and working principle of ZHJ series 3 in 1 H Beam Welding Equipment, please check product section of ZHJ8018 Vertical I H Beam Welder and ZHJ8020 I H Beam Fabrication Machine.

C. The Convenience for Operating on Wuxi JACK ZHJ Model 3 in 1 I H Beam Welding Equipment:

Design of Wuxi JACK ZHJ series Vertical I H Beam Welder takes fully consideration on safe and easy operation on the 3 in 1 I H T Beam Welding Machine, for guaranteeing the most ideal ergonomics condition for operator:

1. The central operating area of the I H Beam Fabrication Machine is an area of around 2,000mm width by 2,100mm length, and surrounded with lateral brackets for protection. In this way, people can not get access to rolling and transmission part of the 3 in 1 I H Beam Welding Equipment, which may bring hidden harm to them;

2. On the other hand, this makes the central area a bit dark and lacks sufficient light. For this reason, a piece of LED light is installed just above the central working area of the Vertical I H Beam Welder, on the bottom surface of mechanical gantry beam;

3. Safety Assurance: The external transmission units of the Automatic Integral Function I H Beam Welding Machine, including chains and sprocket on the input and output conveyor, and connection between assembling and straightening in the mechanical main body, are all covered with eye catching bright yellow cover;

4. The height of“operating center” in the ZHJ series integral function I H Beam Welding Equipment: Operating panel and control consoles, are at comfortable level for adult male and female people standing and sitting, without strenuous effort;

5. Contingency Management: The exposed rolling rollers for straightening, at workpiece outlet of the integral function I H Beam Welding Machine, which can not be covered, has local button box for quick use, in case of contingency happens.

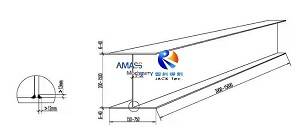

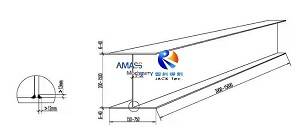

Design sketch on finished output from 3 in 1 H Beam Fabrication Machine: (Fig.1)

4. Technical Parameters ZHJ8015 H Beam Fabrication Machine:

Below are technical specifications of this ZHJ8015 model Integral function I H Beam Welding Equipment (I H T Beam Welding Machine):

Technical Parameter | ZHJ8015 Cost Effective Fit Up Full I H Beam Fabrication Machine (Vertical I H Beam Welder) |

Finished H Beam Web Size | Height: 200 ∼ 1500 mm; Thickness: 6 ∼ 32 mm |

Finished H Beam Flange Size | Width: 150 ∼ 750 mm; Thickness: 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3,000 ∼ 15,000 mm (Can be special made) |

3 in 1 Working Speed of Assembly/ Welding Straightening | Scope: 200∼1200 mm/min.(Stepless, A.C. inverter Control, VFD Working Speed: 500~ 700 mm/min. |

Height of Single Pass Welding Seam | Max. 8~12 mm, flat fillet welding of SAW |

Workpiece Delivered | Welding H Beam / T Beam of Symmetric Section shape Only |

3 in 1 H Beam Fabrication Machine Overall Dimension(L×W×H) | 28m × 4m × 4.2m |

Input / Output Conveyor | 10~11m length each, 3 segments each; One segment with motor, two segments follower |

Driving Mode | Assembly/ Straightening: Hydraulic Cylinder Workpiece Traveling: A.C. motor |

Flange and Web Assembling Way | Hydraulic motor and cylinder automatically in phase |

Hydraulic System Rated Power and Pressure | 4Kw, 4~8 MPa |

Welding Mode | SAW (Submerged Arc Welding), Single Arc or Twin Arc |

Welding Current | Working current: 380~ 750A; Up Limit: 1000 A |